Chromium Boride Powder

Product Description

Chromium boride powder is a chemical compound with important chemical properties and its chemical formula is CrB. The preparation methods of chromium boride powder mainly include high temperature synthesis and molten salt electrolysis. High temperature synthesis method is under high temperature and high pressure, chromium and boron oxide or elemental reaction in the furnace, and then refined and purified to obtain chromium boride powder. Molten salt electrolysis is the use of molten salt electrolysis of chromium oxides or alloys to prepare chromium boride. Chromium boride powder has a wide range of applications. Due to its excellent wear resistance and high temperature stability, it is widely used in the preparation of high strength and high hardness ceramics and alloys. In addition, chromium boride powder can also be used to manufacture new battery materials and high-performance electronic devices.

Specification

| Chromium Boride Powder Composition (%) | |||

| Grade | Purity | B | Cr |

| CrB2-1 | 90% | 9-11% | Bal |

| CrB2-2 | 99% | 9-10% | Bal |

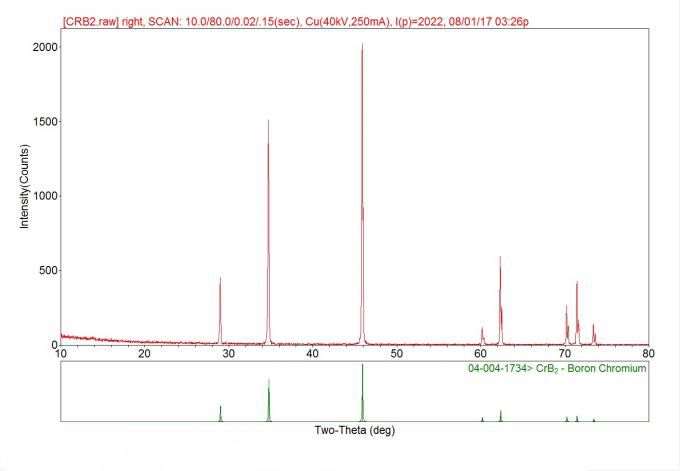

XRD

Application

Chromium boride can be used as wear-resistant, high-temperature oxidation resistant coatings and neutron absorption coatings in nuclear reactors. It can be used in ceramics and melt-blown on the surface of metals and ceramics to form wear-resistant and corrosion-resistant films. It can also be used to spray semiconductor films. Chromium boride and alumina are sintered or hot-pressed products in a slightly oxidizing atmosphere, which has the practical value of high temperature wear resistance.

1. Materials for producing composite ceramics

2. It can be used as neutron absorber

3. Wear resistant coating; crucible lining and corrosion-resistant chemical equipment

4. Composite materials with oxidation resistance

5. Refractory, especially in the case of corrosion resistance of molten metal; heat strengthening additive

6. High temperature and corrosion resistance coating

7. Anti-oxidation special coating.

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.