Cobalt based alloy powder is a kind of high performance metal material, which is composed of cobalt, chromium, molybdenum, iron and other metal elements. It has high strength, high hardness, high wear resistance, high temperature strength and corrosion resistance and other excellent properties, is widely used in aviation, aerospace, automotive, electronics, chemical and other fields.

The main preparation methods of cobalt base alloy powder are organic chemical reduction, mechanical alloying, plasma spraying, etc. Among them, the mechanical alloying method is a more commonly used preparation method, which mixes the metal powder and repeatedly rolls it through mechanical forces such as high-energy ball milling to form a uniform alloy powder.

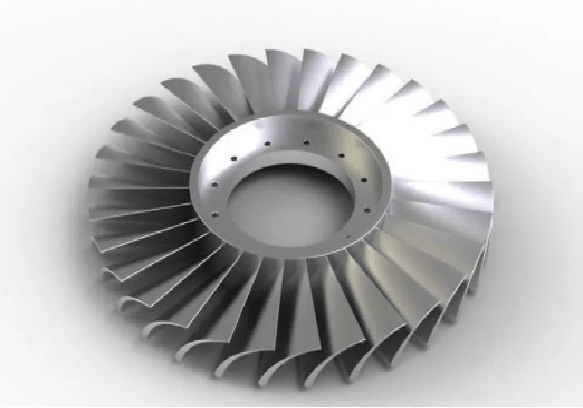

Cobalt based alloy powder has a wide range of applications. In the aerospace field, cobalt-based alloy powder is used to make superalloy blades, turbine discs, combustion chambers and other components to improve the operating temperature and performance of engines. In the automotive sector, cobalt-based alloy powder is used to manufacture high-performance engine components such as valves, piston rings, crankshafts, etc. In the field of electronics, cobalt-based alloy powder is used to manufacture high-performance magnetic materials, such as magnetic heads and disks. In the chemical industry, cobalt-based alloy powder is used to manufacture corrosion-resistant valves, pump bodies and other equipment.

Cobalt-based alloy has good weldability and can be made into castings, such as small molds, blades, nozzles, sealing rings, etc., and can also be made into cast welding rods, tubular welding wires, spray welding alloy powder, etc. Welding wire is often used to repair the hard coating of parts subjected to thermal shock and mechanical shock: because cobalt-based alloys are more expensive, alloy powder is used as a coating on large parts or molds. Compared with nickel base and iron base alloys, cobalt base has better high temperature resistance, wear resistance, low thermal expansion coefficient, high thermal conductivity, making cobalt base alloys can be used in harsher working conditions.

The advantages of cobalt alloy powder are not only its high performance, but also its plasticity and machinability. Cobalt alloy powder can be processed into various shapes of parts, such as plates, pipes, rods, rings, etc., by pressing, sintering, heat treatment and other processes. In addition, cobalt-based alloy powder can also be coated on various substrates by plasma spraying, electrochemical deposition and other processes to improve its wear resistance, corrosion resistance and high temperature strength.

Post time: Jul-27-2023