Electronic paste is an important basic material for manufacturing electronic components. It is widely used in solar photovoltaic modules, chip packaging, printed circuits, sensors and radio frequency identification and other fields. Silver paste is the most important and widely used conductive paste, with a market size of tens of billions. However, silver is a precious metal and is expensive, so it is particularly urgent to develop low-cost and high-performance silver paste replacement paste products. Copper, which has similar electrical and thermal properties to silver, is only 1% of the price of silver. However, copper is easily oxidized in air, so its sintering or curing must be carried out under the protection of inert gases (such as nitrogen, argon, etc.), which greatly limits its application in the field of electronic paste. Therefore, silver coated copper powder that takes into account both price and performance will be a good choice.

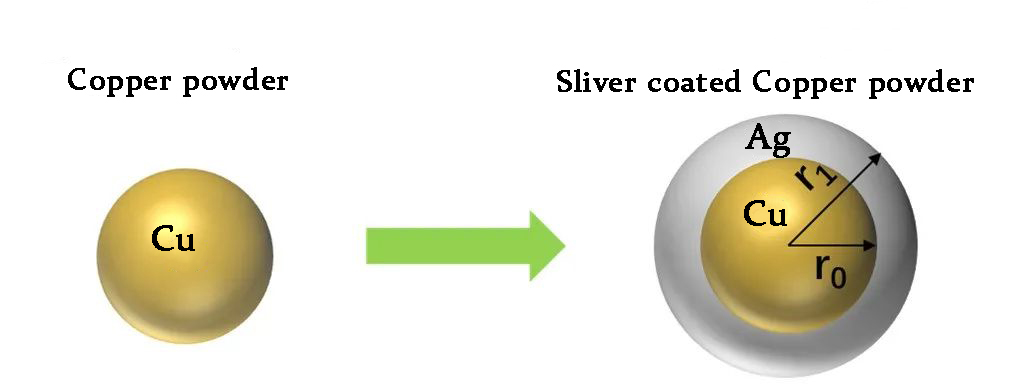

Silver coated copper adopts the technology of silver coated copper particles, which has huge market potential. Huarui production uses electroplating to form a uniform and dense silver coating on the surface of copper powder particles, which can effectively reduce the amount of silver used and thus reduce the cost of paste, and prevent the resistance of copper particles from increasing due to surface oxidation during sintering, etc. question. (Compared with chemical methods, electroplating has a denser silver layer and better oxidation resistance). The silver content can be adjusted according to the ratio of r0 and r1 radii, usually the silver content of silver-coated copper powder is between 10% and 30%.

Silver coated copper powder features:

1) The particle size of silver-coated copper powder is small, up to submicron level.

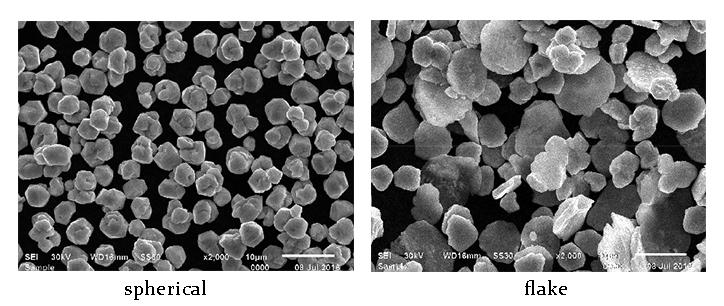

2) The silver-coated copper powder has a lot of morphology, including ball, sheet, dendritic and so on.

3) Silver coated copper powder has excellent electrical conductivity and lower cost, which can replace some application fields of silver powder.

4) Silver coated copper powder has good oxidation resistance and dispersion, and can be used in medium and low temperature paste.

Silver-coated copper powder can be used in conductive adhesives, conductive coatings, conductive ink, polymer pastes, and various microelectronics technology fields that require conductivity and static electricity, and non-conductive material surface metallization. It is a new type of conductive composite Powder. Silver coated copper powder is widely used in electronic, mechanical and electrical, communications, printing, aerospace, military and other industries of conductive, electromagnetic shielding fields. Such as computers, mobile phones, integrated circuits, all kinds of electrical appliances, electronic medical equipment, electronic instruments and other products conductive, electromagnetic shielding

Chengdu Huarui Industrial Co., Ltd.

Email: sales.sup1@cdhrmetal.com

Phone: +86-28-86799441

Post time: Jan-17-2023