Preparation method of titanium powder

The preparation methods of titanium powder mainly include chemical precipitation, molten salt electrolysis, magnesium thermal reduction and so on. Among them, chemical precipitation is the most commonly used method, which reacts with various acids of titanium hydroxide to produce titanium salts, and then reacts with various precipitating agents to produce titanium precipitates. Molten salt electrolysis and magnesium thermal reduction are used to electrolyze titanium compounds at high temperatures, or to generate titanium powder using the reducibility of magnesium metal.

The application of titanium powder

Titanium powder is a high-performance material, with high strength, corrosion resistance, low density and other characteristics, widely used in aerospace, automotive, electronics, medical, chemical and other fields. In the aerospace field, titanium powder can be used to make planes

Aircraft, rockets, satellites and other high-performance products; In the automotive field, titanium powder can be used to manufacture auto parts to improve the performance and life of cars; In the field of electronics, titanium powder can be used to manufacture electronic product shells to improve the beauty and durability of products; In the medical field, titanium powder can be used to manufacture medical devices to improve medical effects and safety; In the field of chemical industry, titanium powder can be used to manufacture chemical equipment to improve the corrosion resistance and service life of equipment.

Titanium powder market prospects

With the continuous progress of science and technology and the continuous development of economy, the application field of titanium powder continues to expand, and the market demand is also increasing. In the future, with the continuous development of aerospace, automotive, electronics, medical and other industries, as well as the continuous improvement of titanium powder production process and cost reduction, the market prospect of titanium powder will be broader. At the same time, with the continuous improvement of environmental awareness, titanium powder as an environmentally friendly material will also be more widely used.

Titanium powder production process and equipment

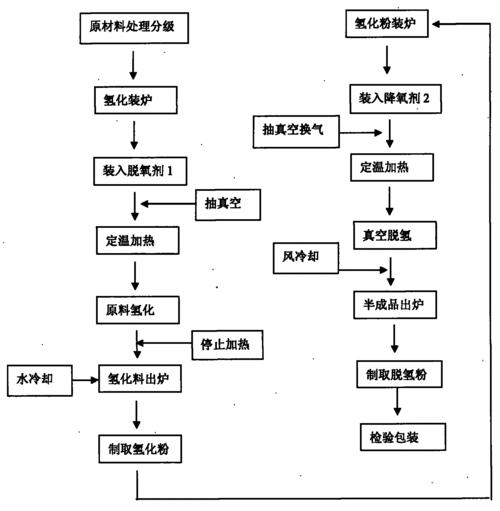

The production process of titanium powder mainly includes raw material preparation, precipitation, filtration, drying, calcination and other links. Among them, precipitation and drying is the key link, it is necessary to control the amount of precipitating agent, precipitation time, drying temperature and other parameters to ensure product quality and stability.

Titanium powder production equipment mainly includes reactor, precipitator, filter, dryer, calciner and so on. Among them, the reactor and precipitator are the key equipment, and it is necessary to ensure that the material and structure of the equipment can adapt to different reaction conditions and precipitation processes.

At present, many enterprises at home and abroad are actively researching and developing titanium powder production processes and equipment to improve production efficiency and product quality, and reduce production costs and energy consumption.

Chengdu Huarui Industrial Co., Ltd.

Email: sales.sup1@cdhrmetal.com

Phone: +86-28-86799441

Post time: Sep-07-2023