OEM/ODM Factory Tungsten Carbide Cobalt Powder - Spherical Alumina Powder for Thermal Interface Materials – Huarui

OEM/ODM Factory Tungsten Carbide Cobalt Powder - Spherical Alumina Powder for Thermal Interface Materials – Huarui Detail:

Product Description

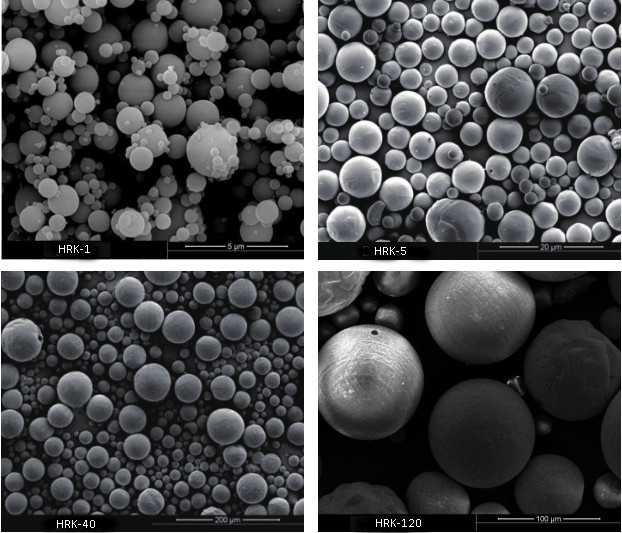

HRK series spherical alumina are produced by high temperature melting-jet method developing on ordinary irregular shape Al2O3, and then undergoes screening, purification and other processes to obtain the final product. The obtained alumina has high spheroidization rate, controllable particle size distribution and high purity. Because of its unique properties such as high thermal conductivity and good mobility, The product have been widely used as the filler of thermal interface materials, thermal engineering plastics and aluminum-based Copper-Clad Laminates and so on.

SEM

Product Features

| Technical item | Unit | HRK Series product Code | ||||||||||

| Particle Size | HRK-1 | HRK-2 | HRK-5 | HRK-10 | HRK-20 | HRK-30 | HRK-40 | HRK-70 | HRK-90 | HRK-120 | ||

| (D10) | µm | 0.71 | 0.69 | 2.54 | 4.55 | 10.5 | 16.88 | 23.77 | 44.32 | 55.23 | 92.39 | |

| (D50) | µm | 1.08 | 2.18 | 5.52 | 10.43 | 20.8 | 30.52 | 41.54 | 71.54 | 87.96 | 122.98 | |

| (D90) | µm | 3.21 | 5.24 | 9.09 | 20.8 | 37.24 | 48.87 | 66.44 | 106.5 | 134.92 | 172.07 | |

| Specific Surface Area | m2/g | 1.69 | 1.27 | 0.36 | 0.17 | 0.14 | 0.13 | 0.12 | 0.12 | 0.1 | 0.06 | |

| Electrical Conductivity | u S/cm | 6.07 | 5.4 | 5.65 | 4.05 | 6.87 | 7.95 | 4.65 | 6.18 | 8.15 | 6.45 | |

| PH Value | - | 7.53 | 7.79 | 7.7 | 7.9 | 7.62 | 7.7 | 7.8 | 7.7 | 7.9 | 7.54 | |

| Moisture | % | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | |

| True Density | g/cm3 | 3.71 | 3.7 | 3.74 | 3.76 | 3.79 | 3.79 | 3.81 | 3.87 | 3.88 | 3.89 | |

| Spheroidization Rate | % | 96 | 98 | 98 | 98 | 96 | 98 | 96 | 96 | 95 | 95 | |

| Chemical Composition | Al2O3 | % | 99.87 | 99.94 | 99.89 | 99.94 | 99.92 | 99.93 | 99.94 | 99.92 | 99.94 | 99.92 |

| SiO2 | ppm | 430 | 30 | 430 | 20 | 150 | 20 | 20 | 30 | 20 | 170 | |

| Fe2O3 | ppm | 140 | 70 | 140 | 40 | 60 | 60 | 50 | 60 | 60 | 140 | |

| Na2O | ppm | 90 | 100 | 10 | 60 | 140 | 90 | 110 | 90 | 70 | 90 | |

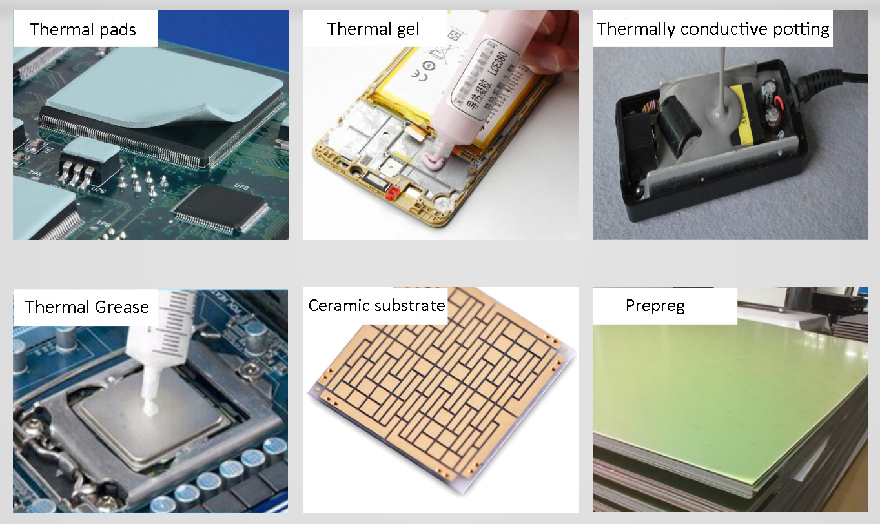

Application

● Thermal Interface Materials: thermal silica pad, thermal grease, thermally conductive potting glue, phase change materials;

● Thermally Conductive Engineering Plastics: LED lamp cover, switch shell,electronic products shell, electrical products heat dissipation parts;

● Al-based Copper Clad Laminate: high-power LED circuit substrate, power circuit boards, etc;

● Alumina Ceramic Filters;

Thermal Spray Coating.

Product detail pictures:

Related Product Guide:

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for OEM/ODM Factory Tungsten Carbide Cobalt Powder - Spherical Alumina Powder for Thermal Interface Materials – Huarui , The product will supply to all over the world, such as: Melbourne, Frankfurt, Slovenia, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.