Chromium Carbide Powder High Purity Supplier

Product Description

Chromium carbide metal chromium (chromium trioxide) and carbon are carbonized in vacuum. Its molecular formula is Cr3C2 (the theoretical weight percentage of carbon is 13%), the density is 6.2g/cm3 and the hardness is above HV2200. The appearance of chromium carbide powder is silver gray.Chromium carbide powder is a high melting point inorganic material with good wear resistance, corrosion resistance and oxidation resistance in high temperature environment (1000-1100 degrees).

Specification details

| Chromium carbide powder for Welding consumable | ||||

| Chemistry/Grade | CrC9 | CrC11 | CrC13 | |

| Cr*≥ | 88 | 87 | 86 | |

| Less than(ppm) | C | 9-11 | 11-13 | 12-14 |

| Si | 0.5 | 0.5 | 0.3 | |

| P | 0.03 | 0.03 | 0.01 | |

| S | 0.05 | 0.03 | 0.05 | |

| Al | 0.5 | 0.5 | 0.25 | |

| Fe | 0.5 | 1 | 0.5 | |

| * The content of Chromium can be adjusted according to customer requirements, between 85-89% | ||||

Advantage

Good flowability Low gas content

Less hollow powder, less satellite powder

High bond strength, and low porosity

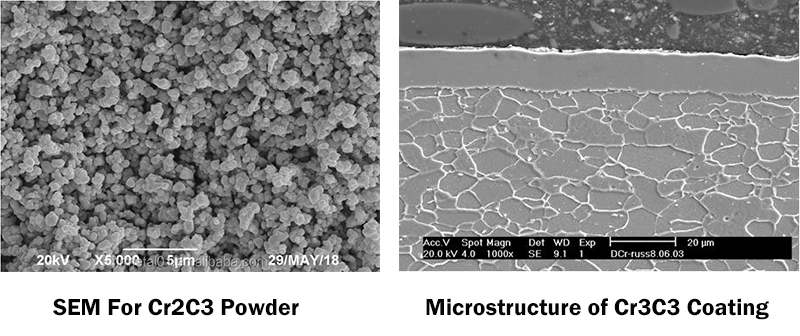

SEM

Main Application

The lattice of chromium carbide is positive and negative, with a melting point of 1895 ° C. Due to its excellent characteristics of high wear resistance, corrosion resistance and high temperature resistance, it is mainly used in:

●Manufacture of special welding materials, surfacing series electrodes, flux-cored wires.

●Cemented carbide, adding Cr3C2 in the production of cemented carbide can not only refine the WC grains, but also improve the strength and hardness of the alloy, and can significantly improve the corrosion resistance of the alloy.

●Thermal spraying powder material, based on Cr3C2 and adding Nicr superalloy to the processed alloy powder, using plasma spraying, can produce high wear-resistant, corrosion-resistant, high-temperature resistant coatings, widely used in fan blades, seals are broken, Boiler "four tubes", etc.

●Arc sprayed wire and submerged arc welded tubular wire, the arc sprayed wire is added with Cr3C2 material, which improves the high temperature resistance and wear resistance. It is used in the repair and preventive maintenance of the "four pipes" of the boiler, and the wear-resistance of the iron-making cloth groove in the metallurgical industry. Lining plate, power plant coal grinding silver, because of the use of Cr3C2 added tubular welding wire surfacing protection, greatly improve the service life.