Application of Boron Carbide Powder

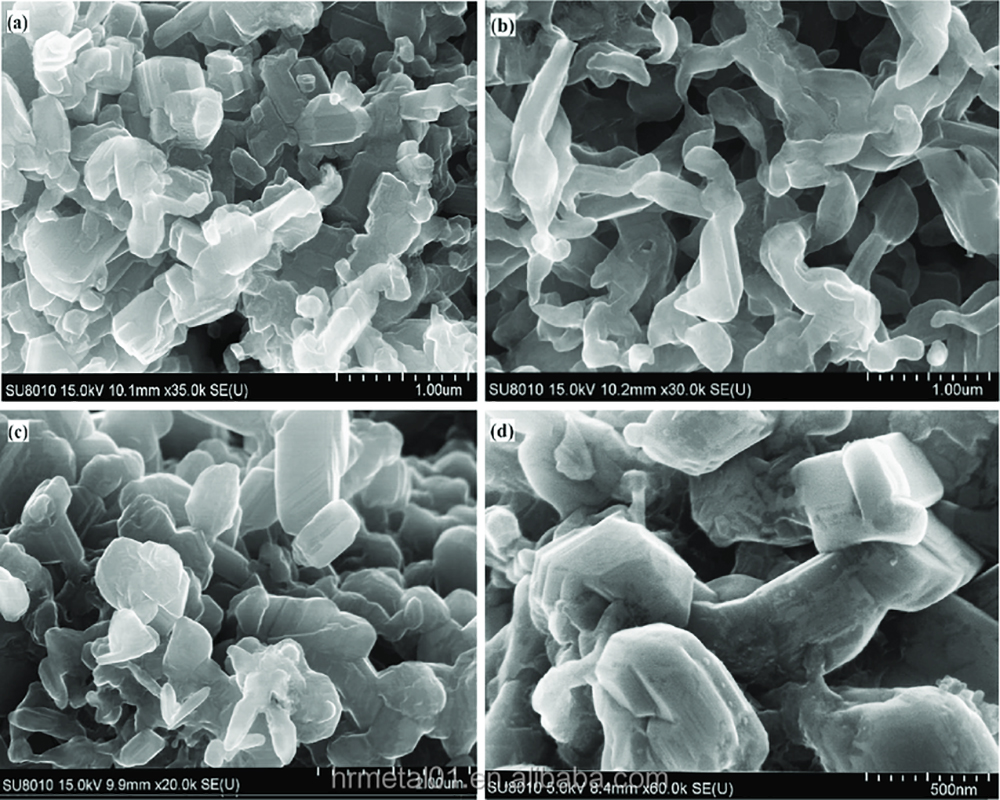

Boron carbide is a black crystal with metallic luster, also known as black diamond, which is an inorganic non-metallic material. The hardness of boron carbide is only after diamond and cubic boron nitride, and it can still maintain high strength at high temperature, which can be used as an ideal high-temperature wear-resistant material; the density of boron carbide is very small (theoretical density is only 2.52 g/cm3), lighter than General ceramic materials can be used in the aerospace field; boron carbide has strong neutron absorption capacity, good thermal stability, and a melting point of 2450 °C, so it is also widely used in the nuclear industry. At the same time, its neutron absorption capacity It can be further improved by adding B element; the boron carbide material with specific morphology and structure also has special photoelectric properties; in addition, boron carbide has high melting point, high elastic modulus, low expansion coefficient and good oxygen absorption capacity, etc. Advantages, all of which make it a potential application material in many fields such as metallurgy, chemical industry, machinery, aerospace and military industry. For example, corrosion-resistant and wear-resistant parts, making bulletproof armor, reactor control rods and thermoelectric elements, etc.

The main applications of boron carbide are as follows:

1.Application of polishing abrasive

The application of boron carbide as abrasive is mainly the polishing of sapphire. In superhard materials, the hardness of boron carbide is superior to that of aluminum oxide and silicon carbide, only inferior to diamond and cubic boron nitride. Boron carbide abrasive (Mohs hardness 9.3) is the most ideal material for processing and grinding sapphire crystals. When boron carbide is above 600 ℃, its surface will be oxidized into B2O3 film, which will soften it to some extent. Therefore, it is not suitable for dry grinding with excessive temperature in abrasive applications, but only for polishing liquid grinding. However, this property can prevent further oxidation of B4C, which makes it have unique advantages in refractory application.

2.Application of refractory materials

Boron carbide has the characteristics of oxidation resistance and high temperature resistance. It is generally used as advanced shaped and amorphous refractories in various fields of metallurgy, such as steel stoves, kiln furniture, etc. Boron carbide will soften at high temperature, so it can adhere to the surface of other material particles. Even if the product is densified, the B2O3 oxide film on its surface can form a certain degree of protection and play an anti-oxidation role. At the same time, because the columnar crystals generated by the reaction are distributed in the matrix and gap of the refractory, the porosity is reduced, the medium temperature strength is improved, and the volume expansion of the generated crystals can heal the volume shrinkage and reduce the cracks.

3.Application of bulletproof materials

Due to its high hardness, high strength, small specific gravity and high elastic resistance, boron carbide is particularly in line with the trend of lightweight bulletproof materials, and is the best bulletproof material for aircraft, vehicles, armor, human body and other protection.

4.Applications in the nuclear industry

Boron carbide has a high neutron absorption cross section and a wide neutron absorption spectrum, which is internationally recognized as the best neutron absorber in the nuclear industry. Boron carbide has rich resources, corrosion resistance, good thermal stability, no radioactive isotopes, low secondary ray energy, etc., so it is widely used as the control material and shielding material in nuclear reactors. Boron carbide will be made into boron carbide rods in the nuclear reactor field, and will also be made into boron carbide powder because of the need to increase the surface area.

Chengdu Huarui Industrial Co., Ltd.

Email: sales.sup1@cdhrmetal.com

Phone: +86-28-86799441

Post time: Oct-08-2022