Spherical Alumina Powder for Thermal Interface Materials

Product Description

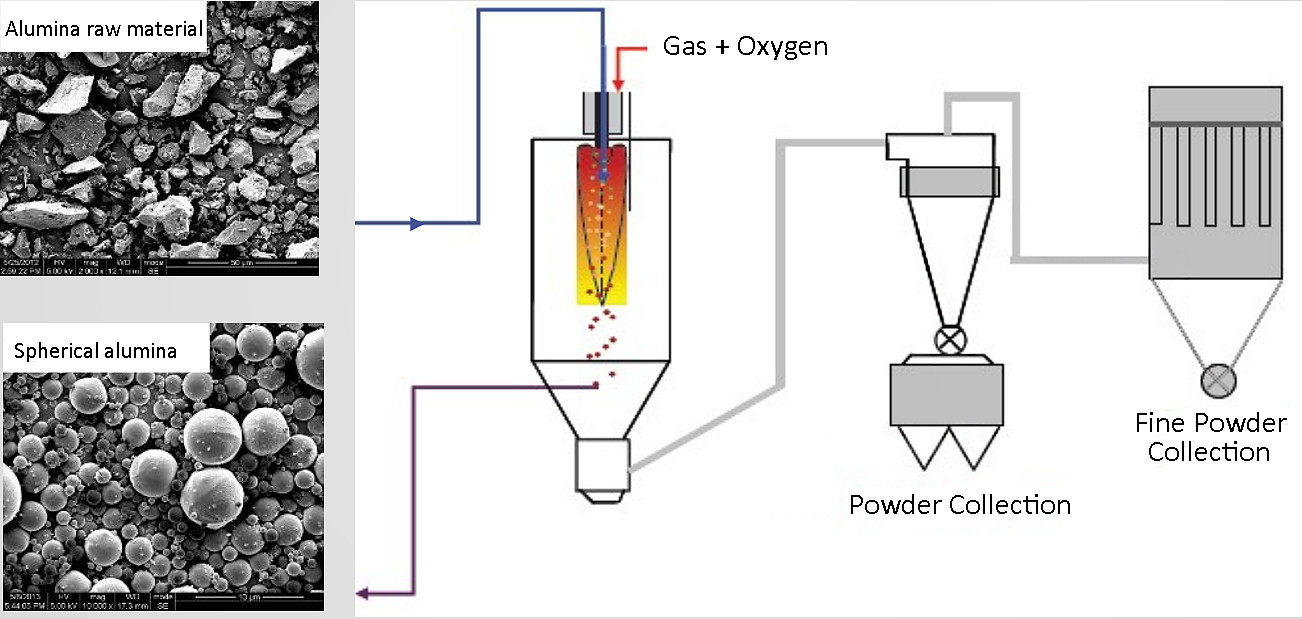

HRK series spherical alumina are produced by high temperature melting-jet method developing on ordinary irregular shape Al2O3, and then undergoes screening, purification and other processes to obtain the final product. The obtained alumina has high spheroidization rate, controllable particle size distribution and high purity. Because of its unique properties such as high thermal conductivity and good mobility, The product have been widely used as the filler of thermal interface materials, thermal engineering plastics and aluminum-based Copper-Clad Laminates and so on.

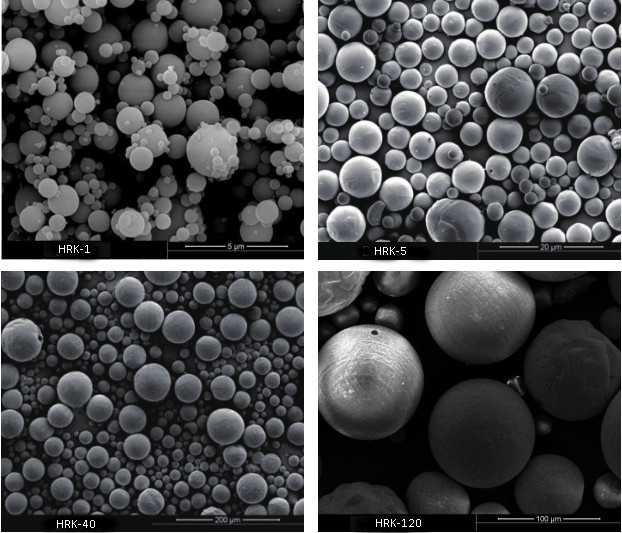

SEM

Product Features

| Technical item | Unit | HRK Series product Code | ||||||||||

| Particle Size | HRK-1 | HRK-2 | HRK-5 | HRK-10 | HRK-20 | HRK-30 | HRK-40 | HRK-70 | HRK-90 | HRK-120 | ||

| (D10) | µm | 0.71 | 0.69 | 2.54 | 4.55 | 10.5 | 16.88 | 23.77 | 44.32 | 55.23 | 92.39 | |

| (D50) | µm | 1.08 | 2.18 | 5.52 | 10.43 | 20.8 | 30.52 | 41.54 | 71.54 | 87.96 | 122.98 | |

| (D90) | µm | 3.21 | 5.24 | 9.09 | 20.8 | 37.24 | 48.87 | 66.44 | 106.5 | 134.92 | 172.07 | |

| Specific Surface Area | m2/g | 1.69 | 1.27 | 0.36 | 0.17 | 0.14 | 0.13 | 0.12 | 0.12 | 0.1 | 0.06 | |

| Electrical Conductivity | u S/cm | 6.07 | 5.4 | 5.65 | 4.05 | 6.87 | 7.95 | 4.65 | 6.18 | 8.15 | 6.45 | |

| PH Value | - | 7.53 | 7.79 | 7.7 | 7.9 | 7.62 | 7.7 | 7.8 | 7.7 | 7.9 | 7.54 | |

| Moisture | % | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | |

| True Density | g/cm3 | 3.71 | 3.7 | 3.74 | 3.76 | 3.79 | 3.79 | 3.81 | 3.87 | 3.88 | 3.89 | |

| Spheroidization Rate | % | 96 | 98 | 98 | 98 | 96 | 98 | 96 | 96 | 95 | 95 | |

| Chemical Composition | Al2O3 | % | 99.87 | 99.94 | 99.89 | 99.94 | 99.92 | 99.93 | 99.94 | 99.92 | 99.94 | 99.92 |

| SiO2 | ppm | 430 | 30 | 430 | 20 | 150 | 20 | 20 | 30 | 20 | 170 | |

| Fe2O3 | ppm | 140 | 70 | 140 | 40 | 60 | 60 | 50 | 60 | 60 | 140 | |

| Na2O | ppm | 90 | 100 | 10 | 60 | 140 | 90 | 110 | 90 | 70 | 90 | |

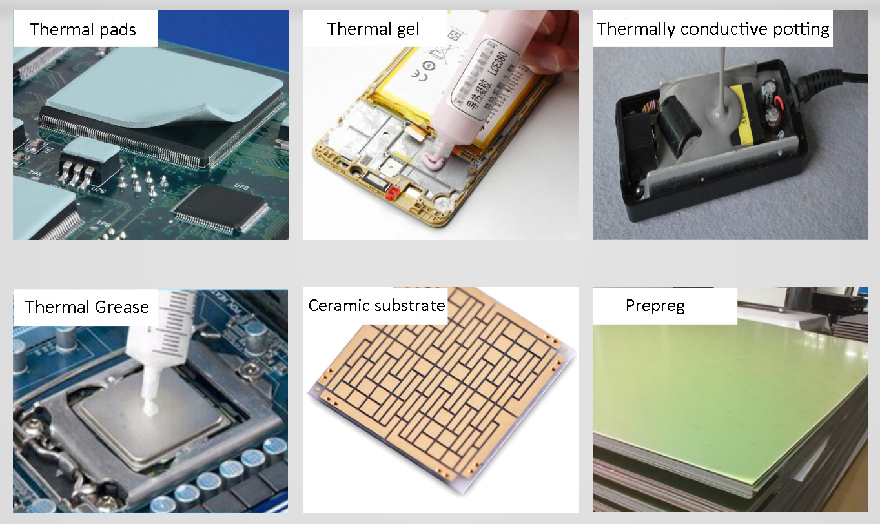

Application

● Thermal Interface Materials: thermal silica pad, thermal grease, thermally conductive potting glue, phase change materials;

● Thermally Conductive Engineering Plastics: LED lamp cover, switch shell,electronic products shell, electrical products heat dissipation parts;

● Al-based Copper Clad Laminate: high-power LED circuit substrate, power circuit boards, etc;

● Alumina Ceramic Filters;

Thermal Spray Coating.