Spherical Alumina: Cost-effective Thermal Conductive Powder Material

With the explosive growth of energy-intensive fields such as 5G and new energy vehicles, thermal conductivity materials will become key materials. As the main filler solution, spherical alumina is regarded as the most cost-effective thermal powder filler in the industry, and it is expected to follow the growth of the thermal conductivity market and and the demand will explode.

The three commonly used fillers are metal fillers, carbon materials, and ceramic materials. Although metal fillers and carbon materials themselves have high thermal conductivity, which can significantly improve the thermal conductivity of polymer materials, they are prone to damage the insulation properties of the materials under high load. And carbon materials such as graphene or carbon nanotubes are not easy to disperse in the matrix, which is not conducive to the formation of an effective thermal conduction pathway. Compared with these two types of fillers, ceramic fillers have attracted more and more attention in the field of preparing high thermal conductivity composites due to their excellent heat transfer properties and high insulation properties. Among them, Al2O3 fillers are widely used and researched because of their high thermal conductivity, high resistivity, low dielectric loss, and high cost performance. Spherical fillers are more conducive to exerting the thermal conduction function of thermally conductive fillers, so the most commonly used thermally conductive filler on the market is mainly spherical alumina powder.

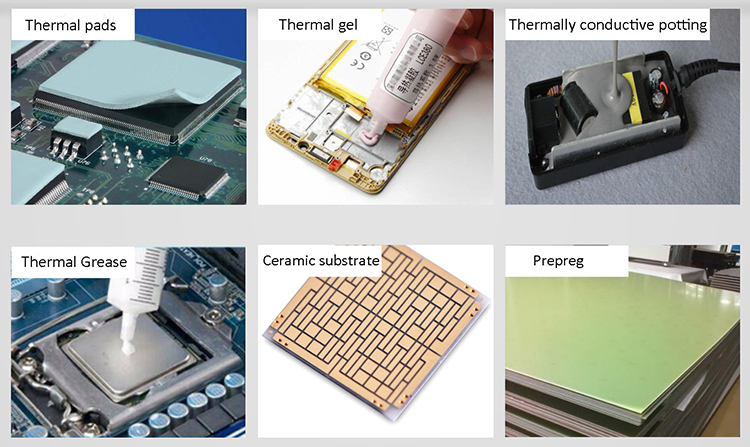

Because of its good thermal conductivity and excellent cost performance, spherical alumina powder is the thermal conductivity filler used in large quantities in the current market thermal interface materials and accounts for a relatively high proportion. Thermal interface materials include thermal gasket, thermal silicone grease, thermal sealing glue and thermal gel, etc. The terminal is used for heat dissipation of various electronic communication equipment, new energy vehicle battery components, power charger components, LED lights, outdoor power supplies, transformers, etc. In addition, the demand for spherical aluminum oxide powder for thermal aluminum base copper clad plate, thermal plastic sealing material, thermal engineering plastics (such as LED lamp shade, electrical appliances, electronic devices), thermal spraying coating materials, special ceramics, and special grinding materials is also gradually increasing.

Chengdu Huarui Industrial Co., Ltd.

Email: sales.sup1@cdhrmetal.com

Phone: +86-28-86799441

Post time: Sep-14-2022