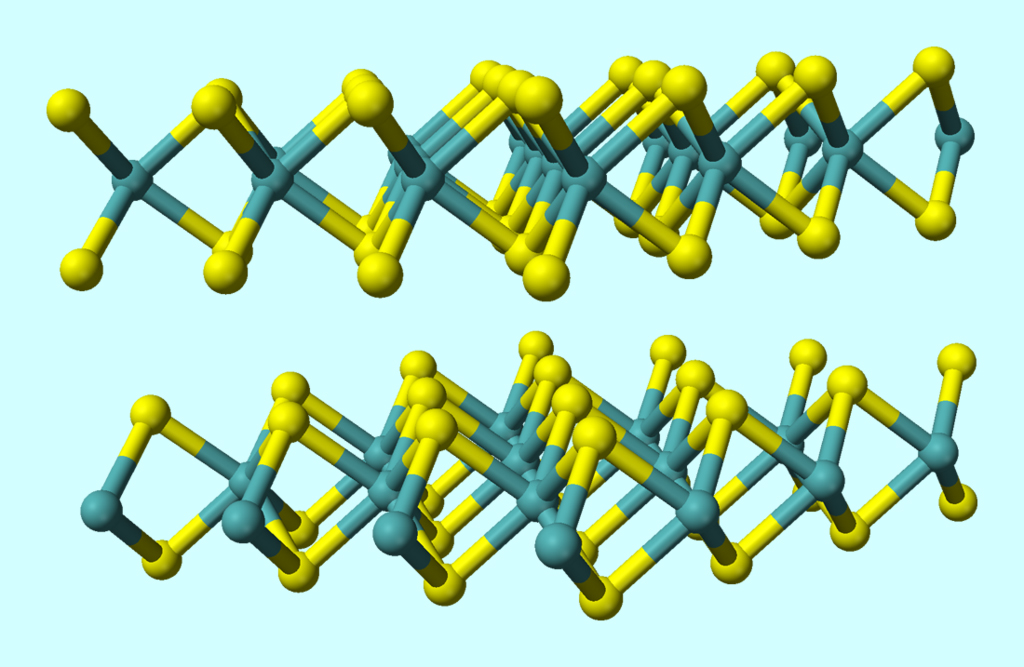

Tungsten disulfide is a compound of tungsten and sulfur, and its appearance is black gray powder. The chemical formula is WS2, and the crystal structure is a layered structure. Tungsten disulfide powder has a very low friction coefficient, high extreme pressure resistance and oxidation resistance, excellent lubricity, and relatively stable chemical properties. Let’s move on to what are the main uses of tungsten disulfide powder.

1.Solid Lubricant

The dynamic friction coefficient of WS2 is 0.030, and the static friction coefficient is 0.070, which is even smaller than that of molybdenum disulfide. Its compressive strength is as high as 2100MPa. Tungsten disulfide powder has the advantages of wide temperature, long lubrication life, low friction coefficient, good acid and alkali resistance, corrosion resistance, and load resistance, so it is often used as a lubricant. It is suitable for lubrication under various harsh conditions such as high temperature, high pressure, high vacuum, high load, high speed, high radiation, strong corrosion, and ultra-low temperature.

2.Petroleum Catalyst

Tungsten disulfide powder can be used as catalyst for hydrogenation, desulfurization, polymerization, reforming, hydration, dehydration and hydroxylation due to its excellent cracking performance, high catalytic activity and long service life.

3.Energy Storage Electrode Material

As a layered material, WS2 is connected by W-S covalent bonds within the layers and van der Waals forces between the layers, and the distance between the layers is relatively moderate, so it has good thermochemical stability, lithium storage performance and fast electron transmission rate, which can effectively improve the energy density and structural stability of electrode materials.

4.Chip Transistor

Tungsten disulfide powder is a low-dimensional transition metal semiconductor material, which enables the manufactured semiconductor components to have stronger data processing and storage capabilities.

5.Additives for High Performance Lubricating Oil

Studies have found that adding an appropriate amount of tungsten disulfide nanoparticles to lubricating oil can greatly improve the lubricating performance of lubricating oil, reduce the friction factor by 20%~50%, and increase the oil film strength by 30%~40%, and its lubricating performance is far better than that of nano MoS2.

Chengdu Huarui Industrial Co., Ltd.

Email: sales.sup1@cdhrmetal.com

Phone: +86-28-86799441

Post time: Mar-17-2023