Nano 99.99% Tungsten Disulfide Powder WS2 powder

Product Description

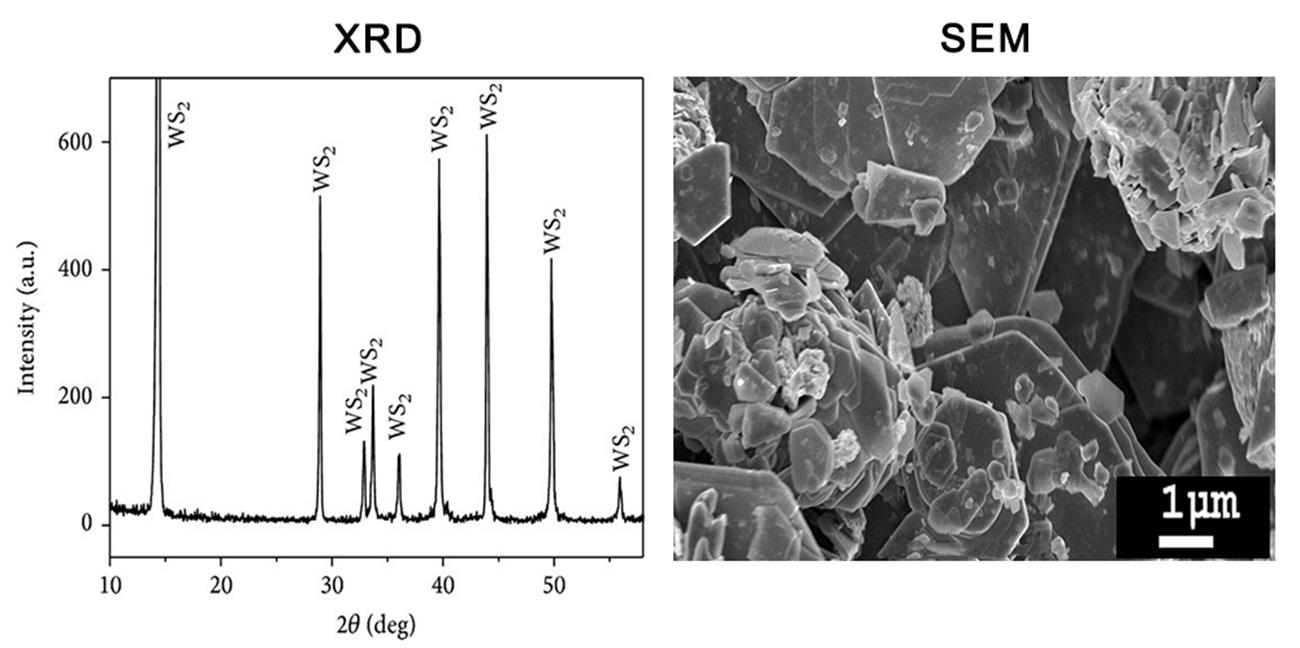

Tungsten disulfide is a compound of tungsten and sulfur, insoluble in water and organic solvents, and does not react with acids and bases. It is a gray-black powder with semiconducting and diamagnetic properties. Tungsten disulfide powder can be used as a lubricant with better performance than molybdenum disulfide, lower friction coefficient and higher compressive strength.

Specification

| Specifications of Tungsten Disulfide powder | |

| Purity | >99.9% |

| Size | Fsss=0.4~0.7μm |

| Fsss=0.85~1.15μm | |

| Fsss=90nm | |

| CAS | 12138-09-9 |

| EINECS | 235-243-3 |

| MOQ | 5kg |

| Density | 7.5 g/cm3 |

| SSA | 80 m2/g |

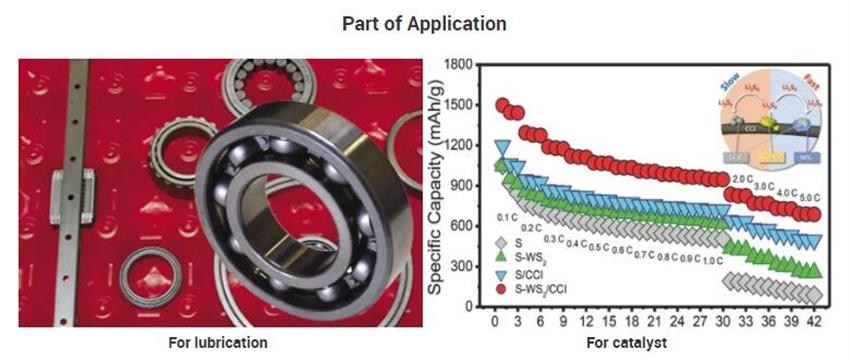

Application

1) Solid additives for lubricating grease

Mixing micron powder with grease at a ratio of 3% to 15% can enhance the high temperature stability, extreme pressure and anti-wear properties of the grease and prolong the service life of the grease.

Dispersing nano tungsten disulfide powder into lubricating oil can enhance lubricity (friction reduction) and anti-wear properties of lubricating oil, because nano tungsten disulfide is a powerful antioxidant, which can greatly prolong the service life of lubricating oil.

2) Lubrication coating

Tungsten disulfide powder can be sprayed on the surface of the substrate by dry and cold air under the pressure of 0.8Mpa (120psi). Spraying can be carried out at room temperature and the coating is 0.5 micron thick. Alternatively, the powder is mixed with isopropyl alcohol and the sticky substance is applied to the substrate. At present, tungsten disulfide coating has been used in many fields, such as auto parts, aerospace parts, bearings, cutting tools, mold release, valve components, pistons, chains, etc.

3) Catalyst

Tungsten disulfide can also be used as a catalyst in the petrochemical field. Its advantages are high cracking performance, stable and reliable catalytic activity, and long service life.

4) Other applications

Tungsten disulfide is also used as a non-ferrous brush in the carbon industry, and can also be used in superhard materials and welding wire materials.