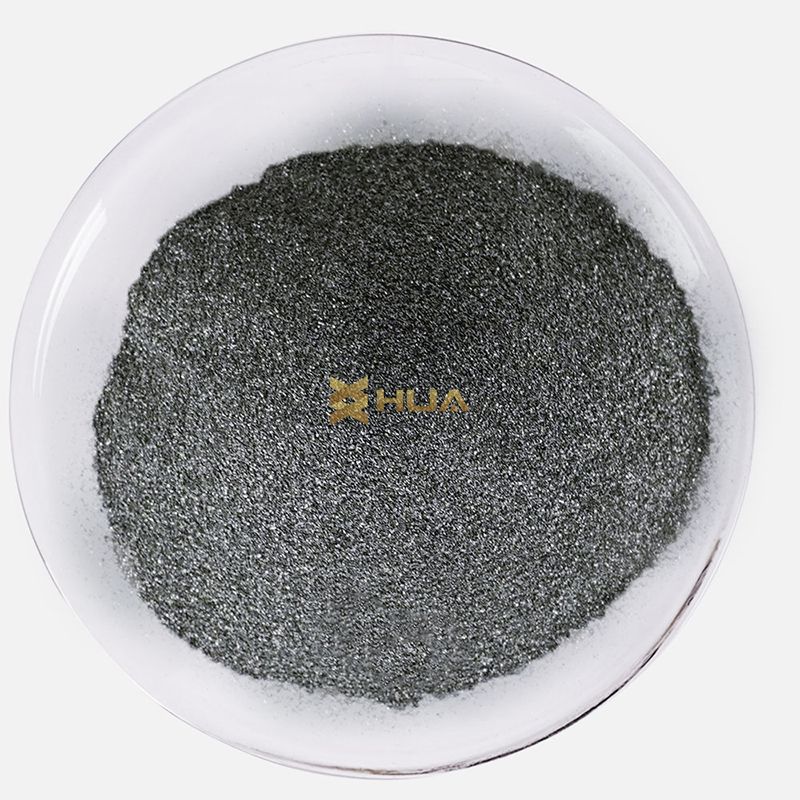

3D Printing Niobium(Nb)Metal Powder for Metallurgical Purposes

Product Description

The chemical composition of niobium powder is mainly niobium oxide, usually niobium pentoxide. Its main production methods are chemical reduction method, electrolytic reduction method and mechanical grinding method. Among them, chemical reduction method and electrolytic reduction method are the main methods of industrial large-scale production of niobium powder, while mechanical grinding method is suitable for small-scale or laboratory preparation of a small amount of high-purity niobium powder. Niobium powder has a wide range of applications in many fields, such as high temperature furnace, electronic device manufacturing, aerospace, metallurgy, biomedicine, etc.

Specification

|

Chemical Composition(wt.%) |

|||

|

Element |

Grade Nb-1 |

Grade Nb-2 |

Grade Nb-3 |

|

Ta |

30 |

50 |

100 |

|

O |

1500 |

2000 |

3000 |

|

N |

200 |

400 |

600 |

|

C |

200 |

300 |

500 |

|

H |

100 |

200 |

300 |

|

Si |

30 |

50 |

50 |

|

Fe |

40 |

60 |

60 |

|

W |

20 |

30 |

30 |

|

Mo |

20 |

30 |

30 |

|

Ti |

20 |

30 |

30 |

|

Mn |

20 |

30 |

30 |

|

Cu |

20 |

30 |

30 |

|

Cr |

20 |

30 |

30 |

|

Ni |

20 |

30 |

30 |

|

Ca |

20 |

30 |

30 |

|

Sn |

20 |

30 |

30 |

|

Al |

20 |

30 |

30 |

|

Mg |

20 |

30 |

30 |

|

P |

20 |

30 |

30 |

|

S |

20 |

30 |

30 |

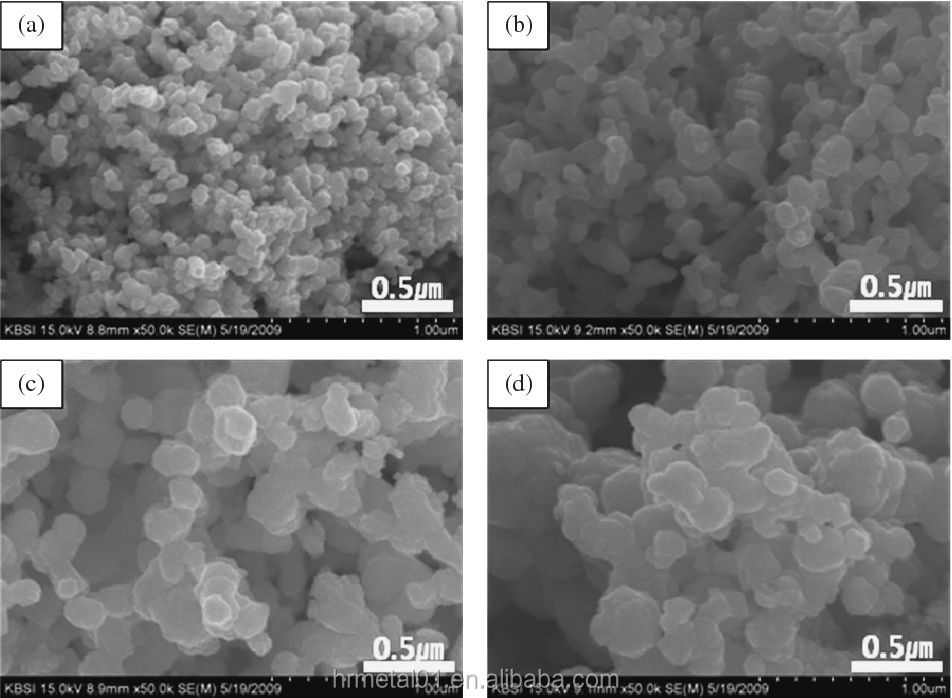

Sem

applications

1. Niobium is a very important superconducting material to produce high-capacity capacitor.

2. Niobium powder is also used to produce tantalum.

3. The pure Niobium metal powder or Niobium Nickel alloy is used to make Nickel, Chrome and Iron base high temperature alloy.

4. Adding 0.001% to 0.1% Niobium powder to change the mechanical properties of steel 5. Used as sealed material of the arc tube.

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.