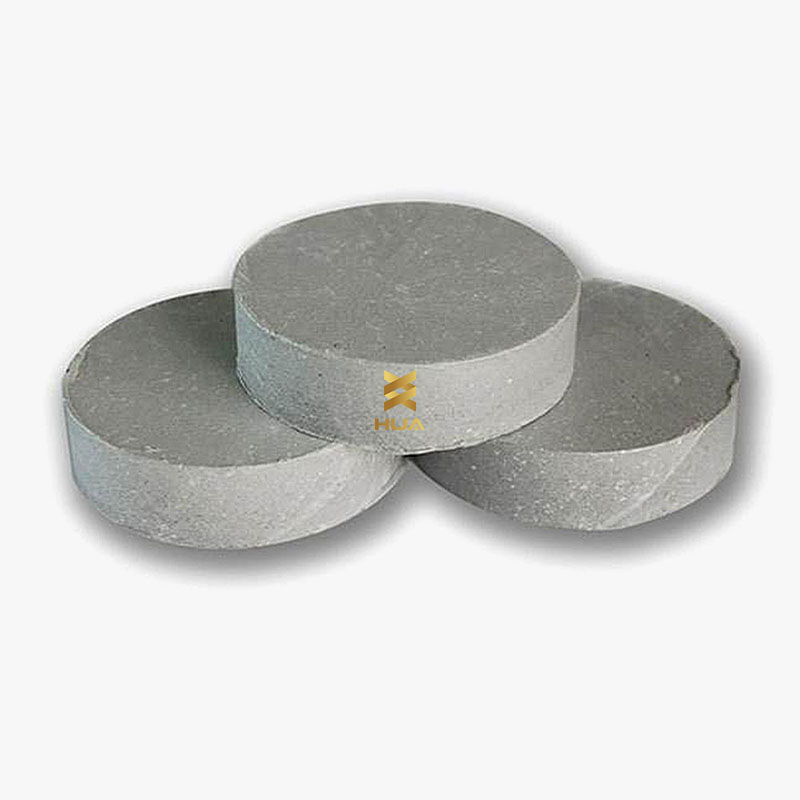

Aluminium alloying additive Cr 75% 80% 85% chromium metal additive tablets for aluminum casting

Product Description

Chromium Additive Tablet is a new product could replace the master alloy used in the steelmaking industry, especially for the superalloy melting. The product is made with pure Chrome metal powder and a certain flux, by a certain proportion of uniform mixing,then press to block shape.

Specification

|

Analysis of Chromium Additive Tablet/Cr tablet: metal powder + other materials |

||

| Metal powderCr: | 75%/80%/85%/90%/95%, or customized | |

| Other materials | A. Pure Aluminum; | |

| B. Non-hygroscopic sodium free flux; | ||

| C. Pure Aluminum + Non-hygroscopic sodium free flux | ||

| Weight |

Tablets |

Min-tablets (Briquettes) |

|

500-1000g |

50-200g |

|

| Guarantee period | 8 months | |

| Packing | inner aluminum foil outer cardboard per 20kg | 10-20kg in kraft paper bag |

Usage Instructions for our Chromium Additive Tablet/Cr tablet

A. remove the scum on the surface of the molten pool, and uniformly input Cr additive tablet in molten pool in the normal operating temperature (740-750℃) , and then standing 20-30 minutes.

B. No need to weight before using

C. all plastic packaging are no chlorine film, can be directly into the furnace, do not produce harmful gases.

D. in order to make the distribution of the alloy elements uniformly recovered fully, in the static to fully mixing of molten pool, 7-15 minutes later, net grilled scum sampling analysis chemical composition.

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.