WC Powder FTC Cast Tungsten Carbide Powder

Product Description

1.Tungsten carbide powder, has high purity, particle size uniform dispersion of good, is an important raw material of producing cemented carbide, nano tungsten carbide powder can make hard alloy has many more excellent properties;

2.Tungsten carbide powder except has high hardness, hard king outside, still has wear resistance, corrosion resistance, temperature, etc;

3. The melting point was 2860°C±50°C, boiling point was 6000°C and also insoluble in water, strong acid resistance, high hardness and elastic modulus.

Specification

|

Cast WC Tungsten Carbide powder composition - % |

||||

|

Grade |

WC-40100 |

WC-40130 |

WC-40140 |

WC-40150 |

|

W |

95-96 |

92-93 |

91-92 |

90-91 |

|

T.C |

3.8-4.1 |

3.8-4.1 |

3.8-4.1 |

3.8-4.1 |

|

F.C |

≦0.08 |

≦0.08 |

≦0.08 |

≦0.08 |

|

Ti |

≦0.1 |

≦0.1 |

≦0.1 |

≦0.1 |

|

Ni |

/ |

2.5-3.5 |

3.5-4.5 |

4.5-5.5 |

|

Cr |

≦0.1 |

≦0.1 |

≦0.1 |

≦0.1 |

|

V |

≦0.05 |

≦0.05 |

≦0.05 |

≦0.05 |

|

Si |

≦0.02 |

≦0.02 |

≦0.02 |

≦0.02 |

|

Fe |

≦0.3 |

≦0.3 |

≦0.3 |

≦0.3 |

|

O |

≦0.05 |

≦0.05 |

≦0.05 |

≦0.05 |

Application

1.Tungsten carbide powder applied in composite materials, improve its performance: Tungsten carbide-cobalt (WC-Co) composite performance carbide powder preparation is the main raw materials and wear-resisting coating. Such as: cutting tools, computer, machinery, etc;

2. Tungsten carbide powder appropriate under high temperature on mechanical processing, can produce cutting tools, kiln of structural materials, the jet engines, gas turbines and nozzle, etc.

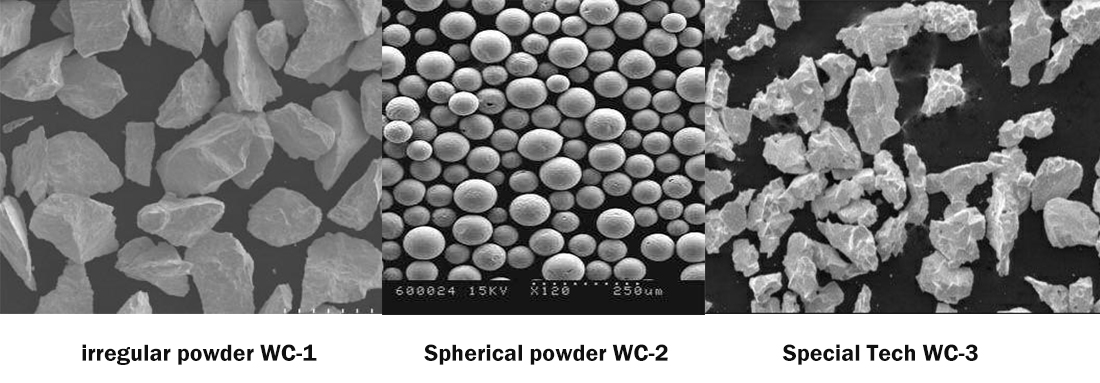

SEM

Quality control system

1.Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

2.Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.