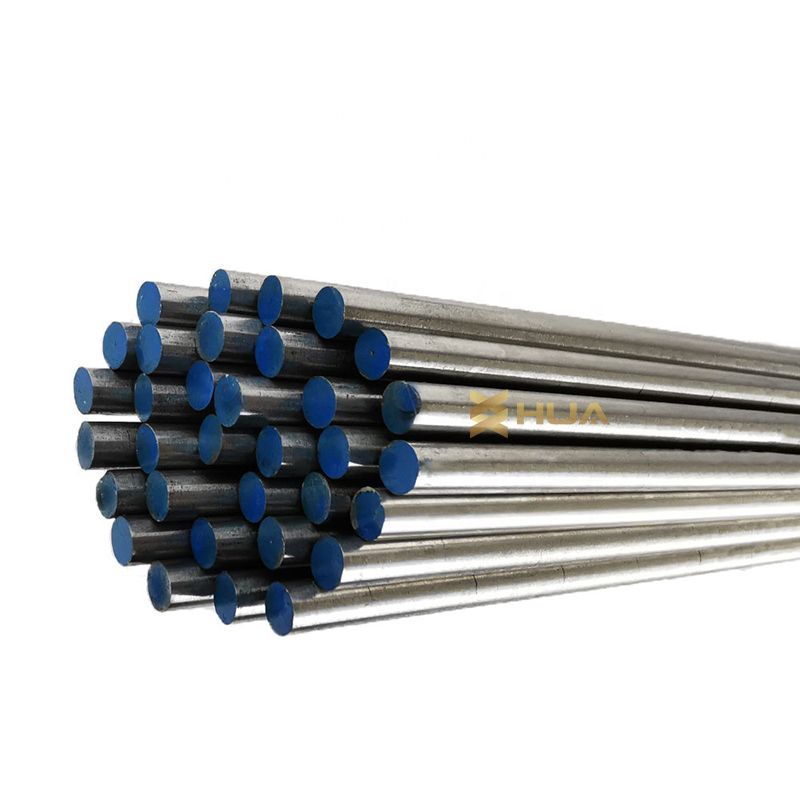

Cobalt Base Alloy welding Rods

Product Description

Cobalt base rod is a kind of alloy material with high strength, good corrosion resistance and good machinability.

The cobalt-based rod has high strength, which allows it to maintain its shape and structure even under high stress and load; The cobalt-based rod has good corrosion resistance, which enables it to maintain its structure and properties when exposed to corrosive environments; The cobalt base rod has good processing properties, which allows it to be processed and treated by different processing processes. This processability makes cobalt-based rods an easy material to process and handle in the manufacturing and processing fields.

Specification

| NO | Chemical composition(%) | ||||||||

| C | Cr | Si | W | Ni | Fe | Mn | Mo | Co | |

| HR-DCo1 | 2.1 | 30 | 1 | 14 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo6 | 1 | 30 | 1 | 4.6 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo12 | 1.4 | 30 | 1 | 9 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo21 | 0.2 | 28 | 1 | --- | ≤3.0 | ≤5.0 | ≤2.0 | 5.5 | Bal |

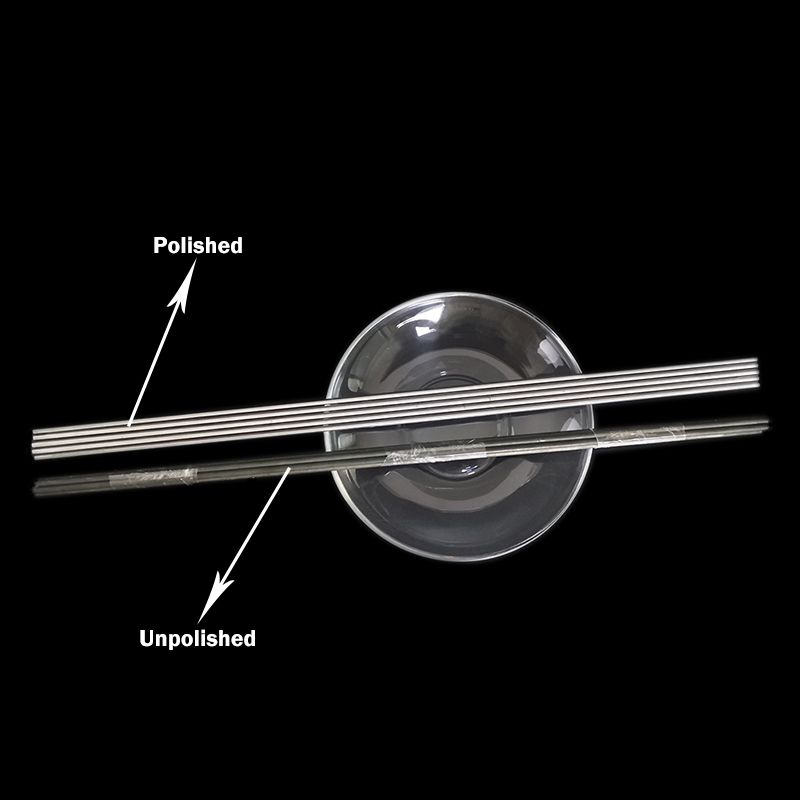

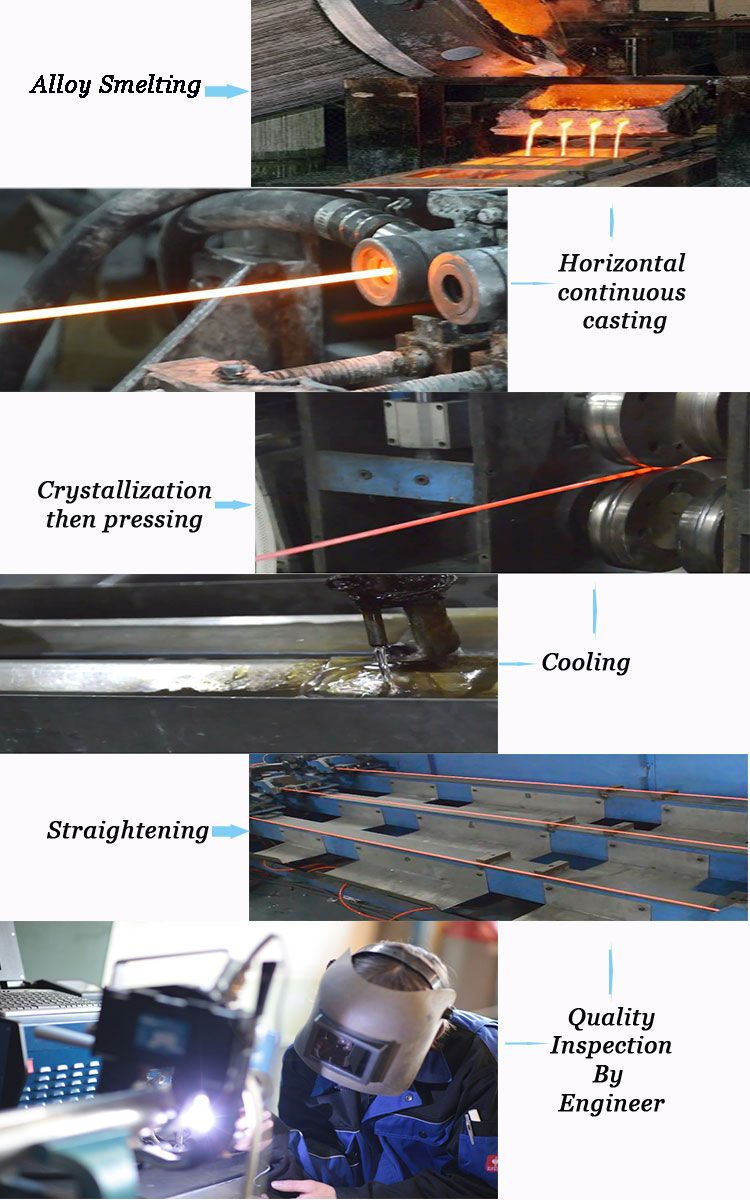

Production process

Application

It is used for occasions where good performance is required under the conditions of wear and corrosion resistance at high temperature. Such as automobiles, internal combustion engine valves, high temperature and high pressure valves, hot shear blades, inner and outer rings of bearings, hot forging dies, etc.

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.