Copper Alloy Welding Material Copper Phosphorus Alloy Cup14

Product Description

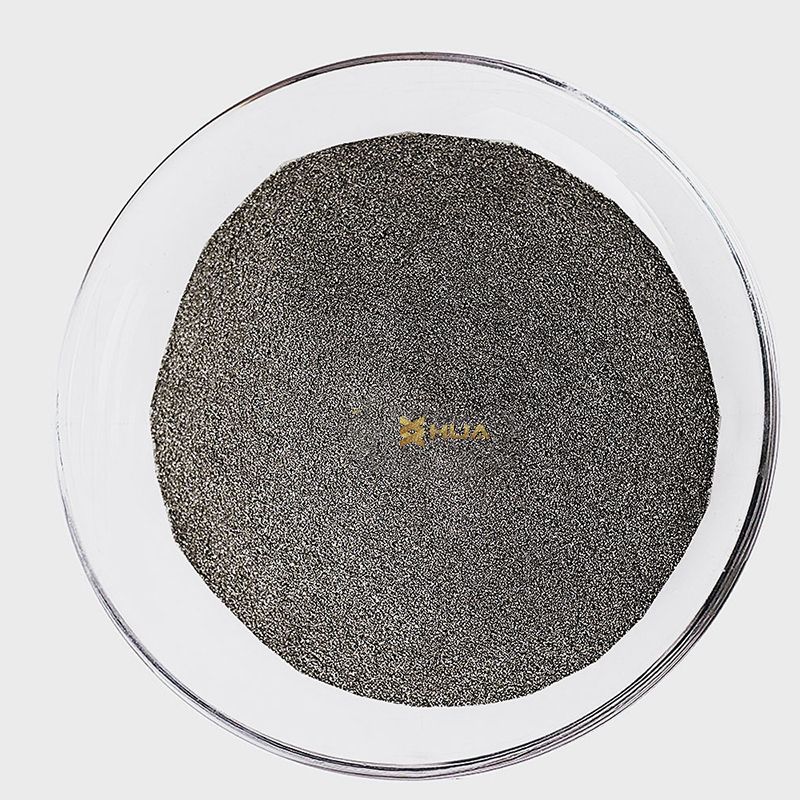

Copper phosphorus alloy is made of high quality electrolytic copper and red phosphorus by advanced phosphorus pressing process. This product is a block with a silver metallic luster. The phosphorus content of copper phosphorus alloy reaches 14%-15%. Copper phosphorus is an excellent deoxidizer. It can effectively remove the oxygen particles in the molten metal, and effectively improve the quality and yield of castings. Copper phosphorus master alloy plays a very important role in the field of non-ferrous casting

Specification

| Product | Copper Phosphorus (CuP) Master Alloy | |||||||

| Typical Trademark | CuP17, CuP14, CuP10 & CuP8 | |||||||

| P | Zn | Pb | Sb | As | Cd | Fe | Cu | |

| Specifications | 14-15 | ≤ | ||||||

| CuP14(%) | 0.01 | 0.02 | 0.05 | 0.003 | 0.005 | 0.02 | Bal | |

Application

1. Copper phosphorus alloy is used in the smelting of copper and copper alloys. It can effectively remove oxygen in the copper melt and significantly reduce oxide inclusions, thus improving the mechanical properties of the alloy. The melting temperature of this product is 900-1020℃.

2. It is used for deoxidizing copper, tin bronze, lead bronze, chromium bronze, manganese bronze, brass, zinc white copper and oxygen-free copper during melting.

Usage method:

1. Bake and dry before use.

2. Put the product into the melt gently, stir evenly, and let it stand for 10-15 minutes.

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.

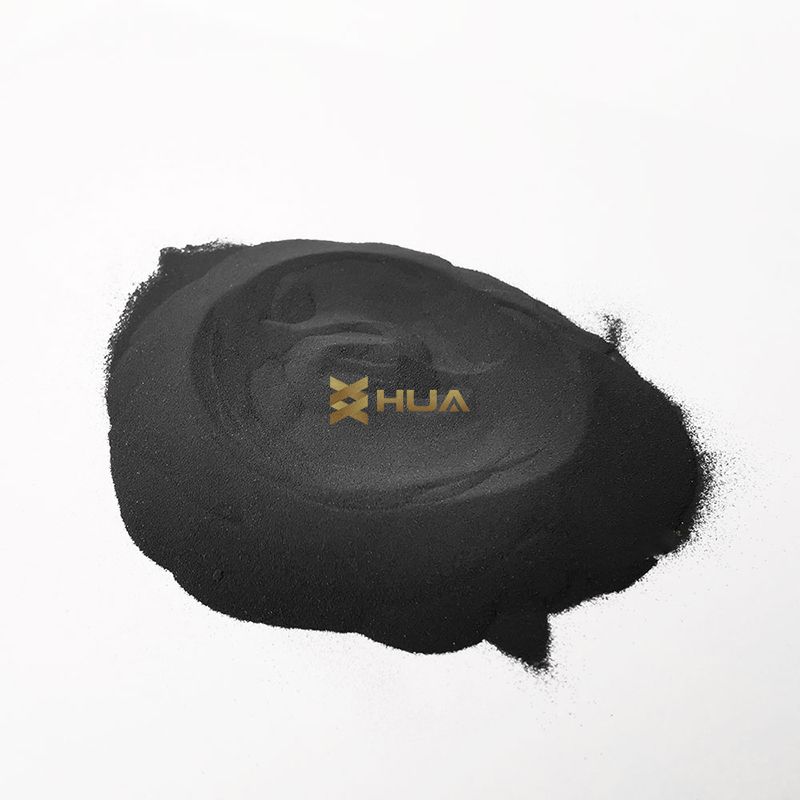

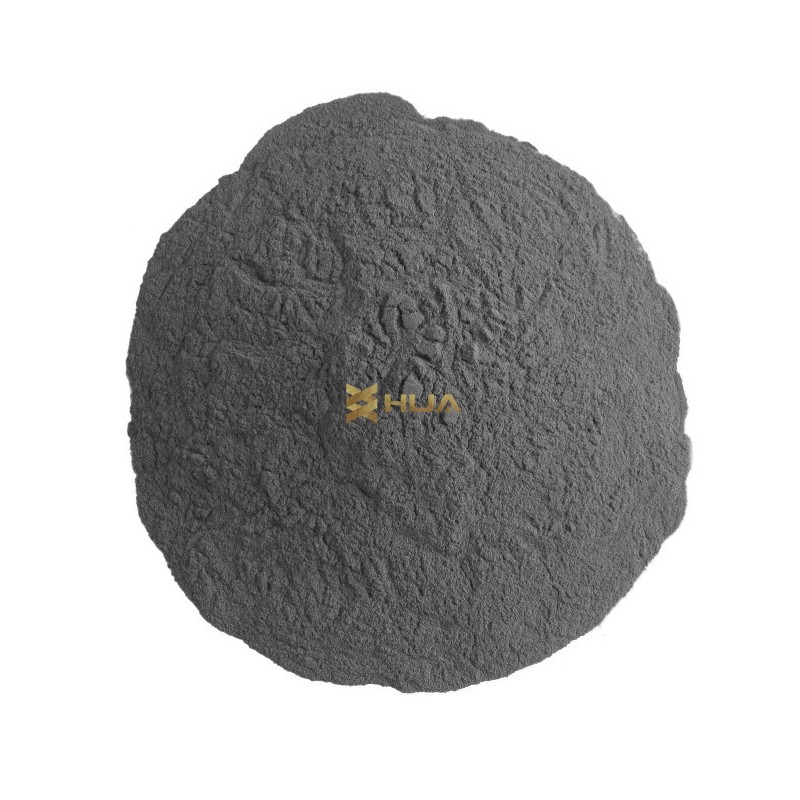

Related Product

We also supply copper phosphorus alloy lump and powder, welcome to inquiry!