Titanium Carbide Powder TiC for Cemented Carbide

Product Description

Titanium carbide is a known hard carbide and is an important raw material for the production of cemented carbide. TiC has the characteristics of high thermal hardness, small friction coefficient and low thermal conductivity, so the tools containing TiC have higher cutting speed and longer service life than those of WC and other materials. If a thin layer of TiC is deposited on the tool surface of other materials (such as WC), the performance of the tool can be greatly improved

Specification

|

Item |

HR-19TiC |

HR-18TiC |

HR-25TiC |

|

Total C. |

>19 |

18-19 |

25 |

|

F.C |

<0.4 |

<0.2 |

<0.2 |

|

O |

<0.45 |

<0.8 |

<0.8 |

|

<0.6 |

|||

|

N |

<0.4 |

<0.45 |

<0.45 |

|

<0.05 |

|||

|

Si |

<0.08 |

<0.08 |

<0.08 |

|

Na |

<0.05 |

<0.05 |

<0.05 |

|

K |

<0.05 |

<0.05 |

<0.05 |

|

Al |

<0.015 |

<0.015 |

<0.015 |

|

Size(FSSS) |

0.5-1um |

0.5-1um |

0.5-1um |

|

1-2um |

1-2um |

1-2um |

|

|

2-5um |

2-5um |

2-5um |

Application

1. Used as additives for cutting tool materials and metal bismuth, zinc, cadmium melting crucibles,

2. Preparation of semiconductor wear-resistant films, HDD large-capacity memory devices.

3. It is an important component of cemented carbide and is used as a deoxidizer in the steelmaking industry.

4. Used as cermet, it has the characteristics of high hardness, corrosion resistance and good thermal stability

5. Titanium carbide powder can also be used in high temperature resistant thermal spraying materials, welding materials, hard film materials, military aviation materials, etc

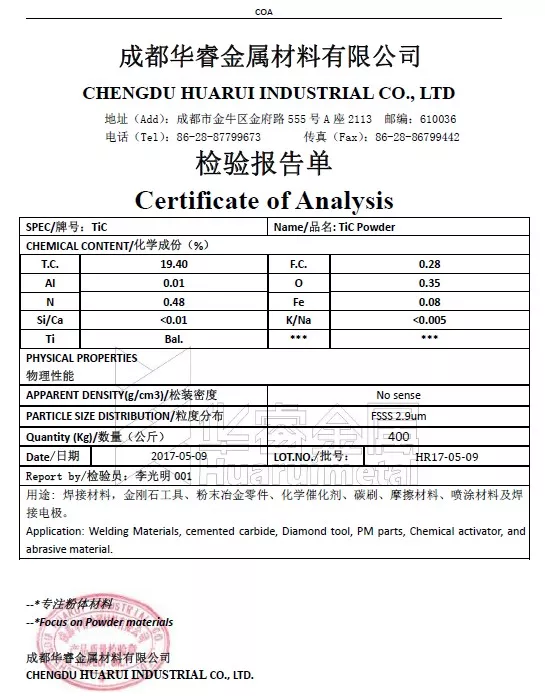

COA

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.