spherical high purity niobium carbide powder

Product Description

Niobium carbide powder is a kind of inorganic nonmetallic material with important application value. It is mainly composed of niobium and carbon, and has excellent physical, chemical and mechanical properties. The main processes of producing niobium carbide powder include carbothermal reduction method and molten salt electrolysis method. Among them, carbothermal reduction method is the most commonly used one, the principle is to reduce niobium oxide or niobium alloy with carbon at high temperature to obtain niobium carbide powder. The method of molten salt electrolysis is to use the mixture of niobium salt and carbon salt to electrolysis at high temperature, so that niobium ion is reduced to niobium carbide on the cathode.

Niobium carbide powder is widely used in many fields, such as electronics, aerospace, machinery, metallurgy and so on. In the field of electronics, niobium carbide can be used to manufacture high-temperature superconducting materials and electronic devices because of its high critical temperature and radiation resistance. In the field of aerospace, niobium carbide alloy has the advantages of high strength, light weight and corrosion resistance, and is a key material in the manufacture of aircraft engines and rocket components.

Specification details

| Niobium Carbide Powder Chemical Composition (%) | ||

| Chemical composition | NbC-1 | NbC-2 |

| CT | ≥11.0 | ≥10.0 |

| CF | ≤0.10 | ≤0.3 |

| Fe | ≤0.1 | ≤0.1 |

| Si | ≤0.04 | ≤0.05 |

| Al | ≤0.02 | ≤0.02 |

| Ti | - | ≤0.01 |

| W | - | ≤0.01 |

| Mo | - | ≤0.01 |

| Ta | ≤0.5 | ≤0.25 |

| O | ≤0.2 | ≤0.3 |

| N | ≤0.05 | ≤0.05 |

| Cu | ≤0.01 | ≤0.01 |

| Zr | - | ≤0.01 |

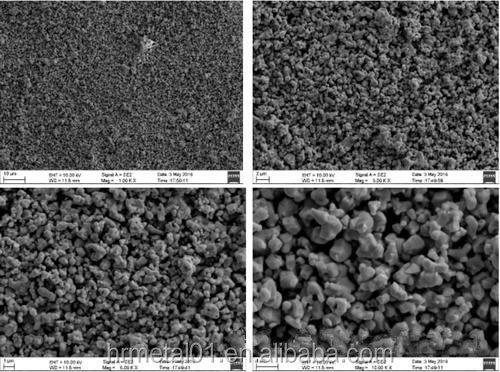

Sem

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.