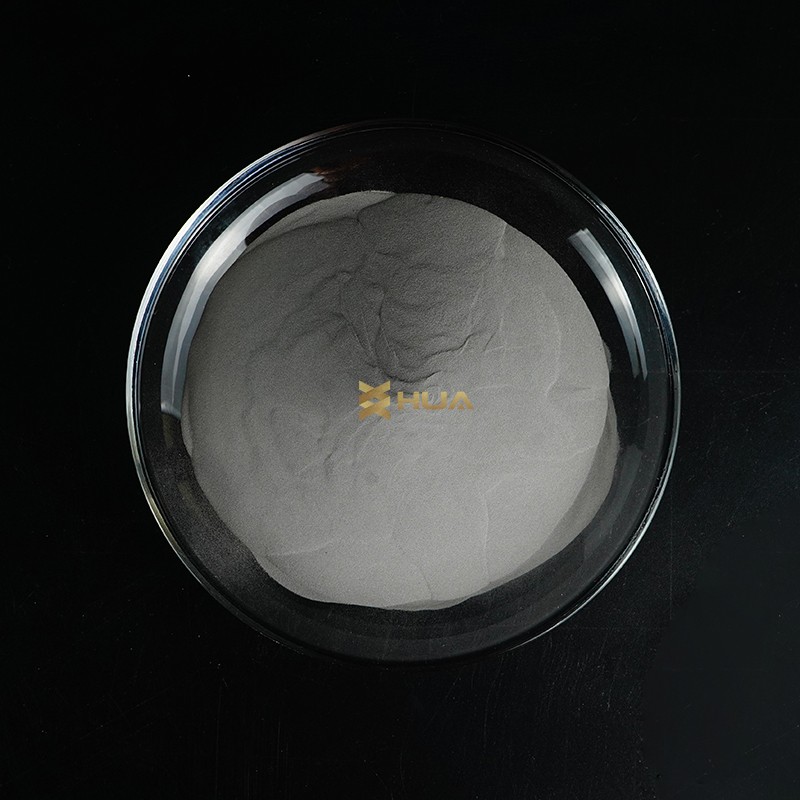

TiB2 Titanium Diboride Powder

Product Description

Titanium diboride is a compound composed of boron and titanium, often abbreviated as TiB2. In terms of physical properties, titanium diboride is a hard black solid with a metallic luster. It has high melting point, high hardness, good electrical conductivity and thermal stability. In terms of chemical properties, titanium diboride is a stable compound, insoluble in water and alkali solutions. It does not react with water and oxygen at high temperatures and has certain antioxidant properties. Because titanium diboride has high hardness, high melting point, good electrical conductivity and high temperature stability and other excellent properties, it is widely used in high temperature ceramics, electronic equipment, aerospace and automotive fields. As a high temperature ceramic material, it can be used to manufacture parts with high strength and high hardness. In electronic devices, titanium diboride can be used to manufacture high-temperature transistors, field-effect transistors and integrated circuits. In addition, it can also be used in the manufacture of high-strength steel and alloy reinforcement agents and surface coatings.

Specification details

| TiB2 | 99% |

| Ti | 68% |

| B | 30% |

| Fe | 0.10% |

| Al | 0.05% |

| Si | 0.05% |

| C | 0.15% |

| N | 0.05% |

| O | 0.50% |

| Other | 0.80% |

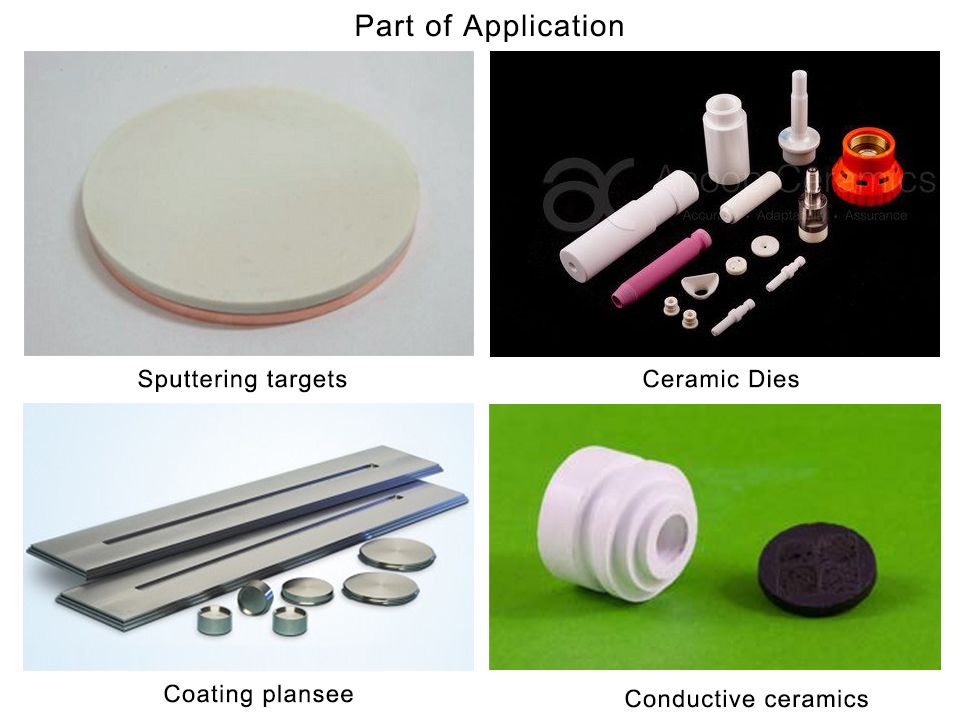

Application

1. Conductive ceramic materials

It is one of the main raw materials of vacuum coating conductive evaporation boat.

2. Ceramic cutting tools and dies

It can be used to manufacture finishing tools, wire drawing dies, extrusion dies, sandblasting nozzles, sealing components and so on.

3. Composite ceramic materials

It can be used as an important component of multi-component composite materials to form composite materials with TiC, TiN, SiC and other materials to make various high-temperature resistant parts and functional parts, such as high-temperature crucibles, engine parts, etc. It is also one of the best materials for making armor protection materials.

4. Cathode coating material for aluminum electrolytic cell

Because of the good wettability between TiB2 and liquid aluminum metal, TiB2 as the cathode coating material of aluminum electrolyzer can reduce the power consumption and prolong the service life of aluminum electrolyzer.

5. PTC heating ceramic materials and flexible PTC materials

It has the characteristics of safety, power saving, reliability, easy processing and molding, etc. It is an updated high-tech product of various electric heating materials.

6. A good strengthening agent for metal materials such as Al, Fe, and Cu.