Thermal Spray WC-Cr3C2-7Ni Powder Tungsten Carbide Based Alloy Powder

Product Description

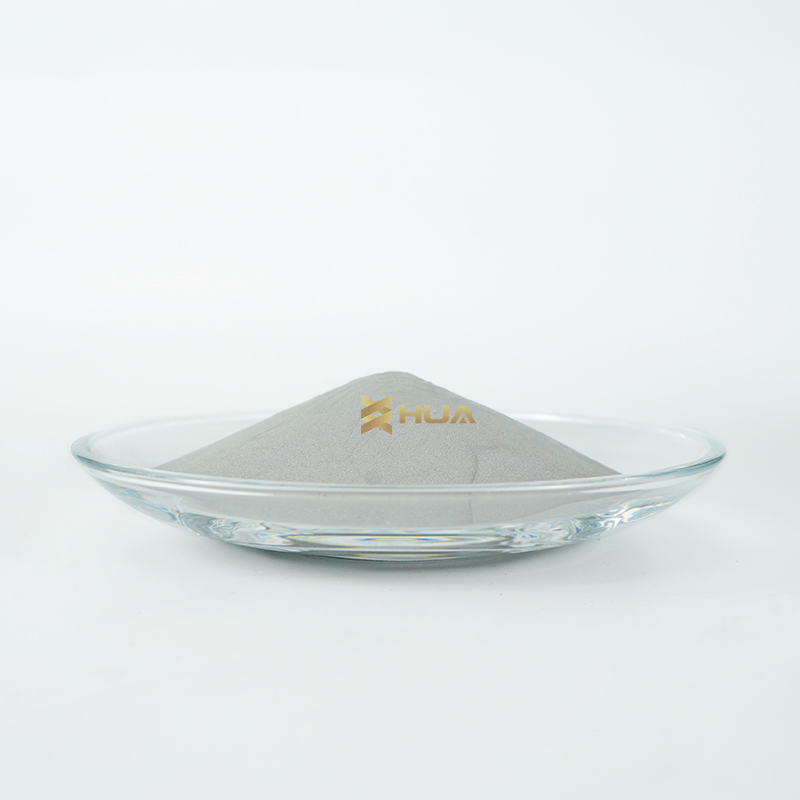

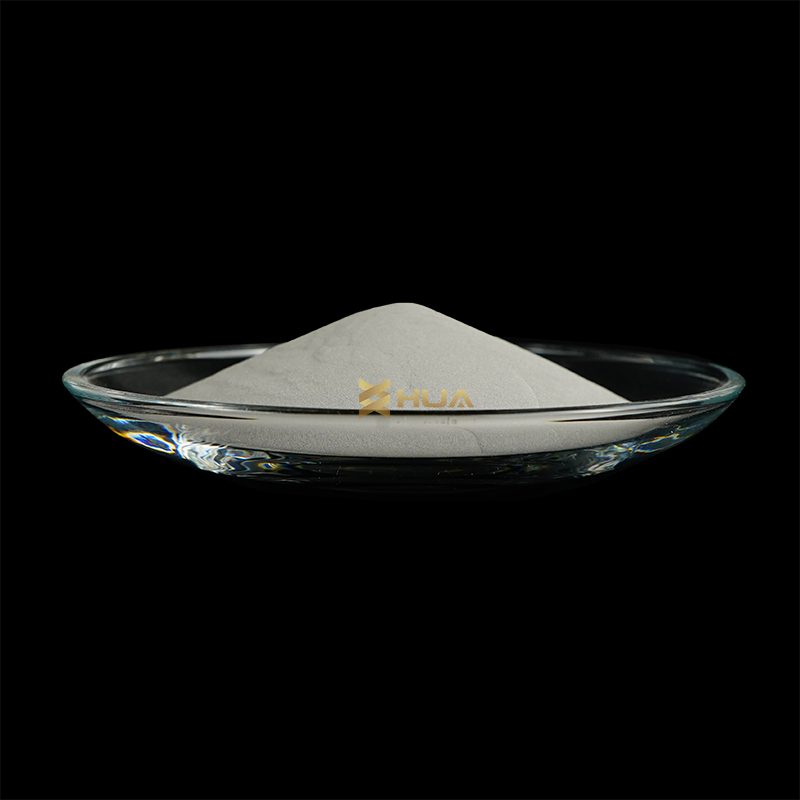

WC-Cr3C2-Ni is a tungsten carbide based coated powder with high hardness. It adopts agglomeration sintering process. Compared with other WC based powders, WC-Cr3C2-Ni has better oxidation resistance and corrosion resistance, better chemical resistance, excellent carbide dispersion promotes better microstructure, better deposition efficiency and density, and smoother coating. 73WC-20Cr3C2-7Ni powder is widely used in oil & gas, chemical industry valve, pump block, sealing ring, and paper making area etc.

Specification

| Formula | WC-CrC-Ni |

| Production technology | Agglomerated & Sintered |

| Apparent density | 4.3-4.8 Typical 4.5 |

| Deposit efficiency | 50-60% |

| Hardness | HV 1200-1300 |

| Size | 5-30um |

| 10-38um | |

| 15-45um | |

| 20-53um | |

| 45-90um | |

| Content | WC-CrC-Ni |

| 73/20/7 | |

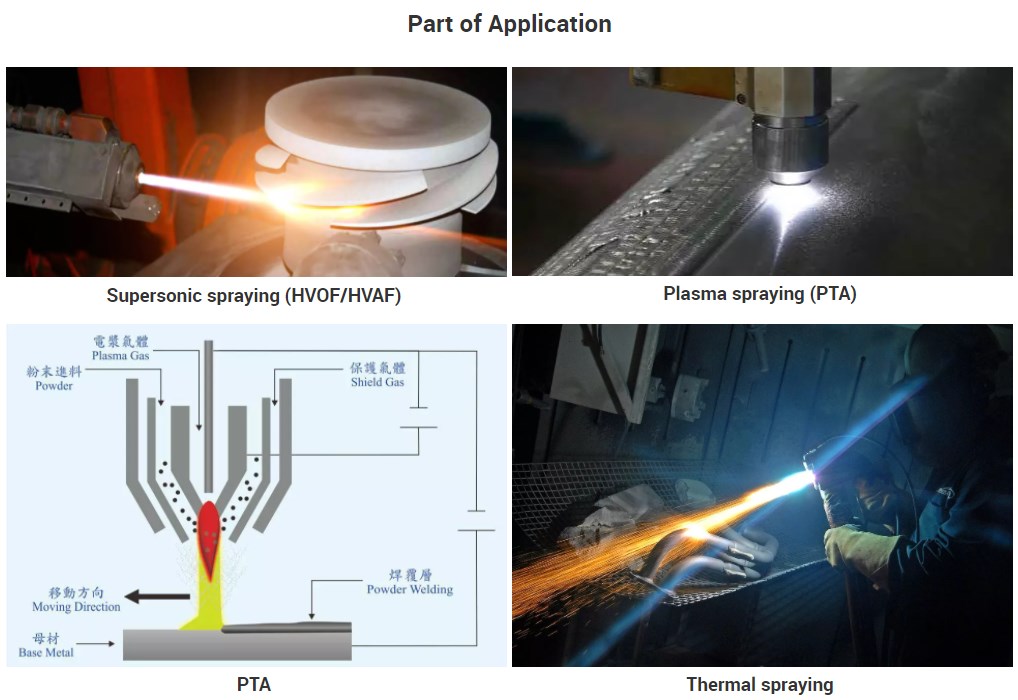

| Application | 1. for plasma spraying (PTA) |

| 2. for supersonic spraying (HVOF/HVAF). |

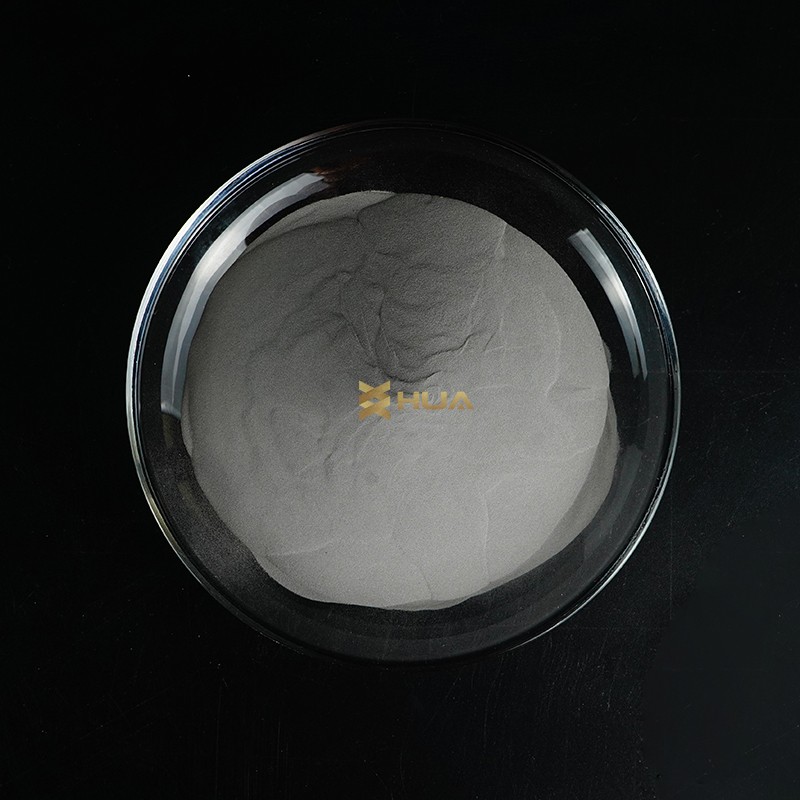

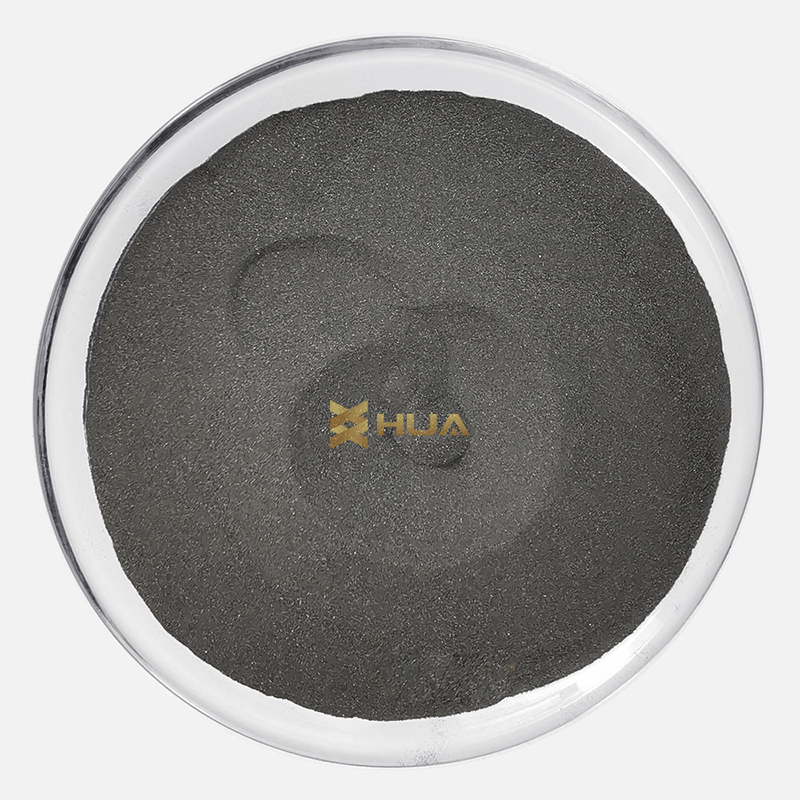

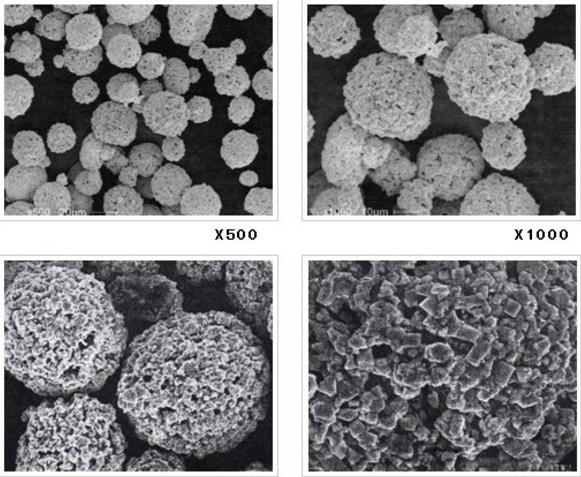

SEM

Application

ApplicationAdvantages of HUARUI Thermal Spray Powder

● High sphericity, low gas content

● Good flowability

● Less hollow powder, less satellite powder

● High bond strength, and low porosity

Related Products

Huarui offer three types of WC powder and various particle sizes for different applications

1. Cast WC powder

2. Spherical cast WC powder

3. Macro-crystal WC powder

Particle size: 1-3um, 10-38um, 15-45um, 15-53um....or customize size.

Tungsten carbide compound powder such as wc-12co/17co and WC-Ni

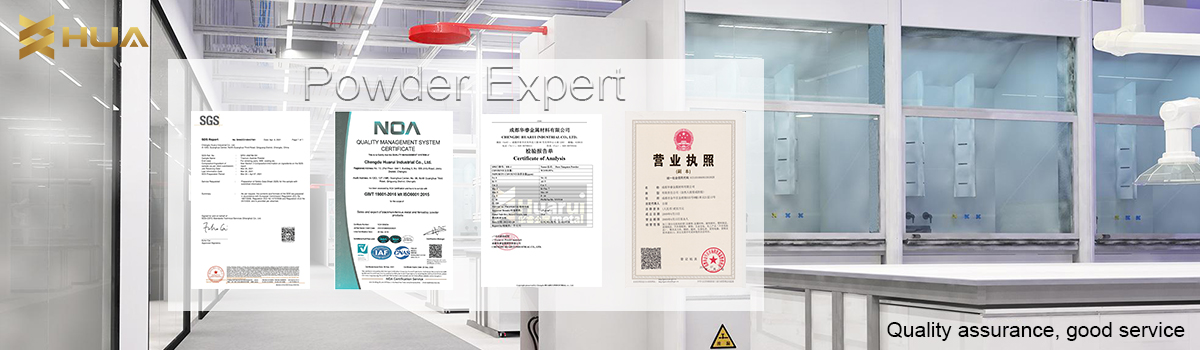

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.