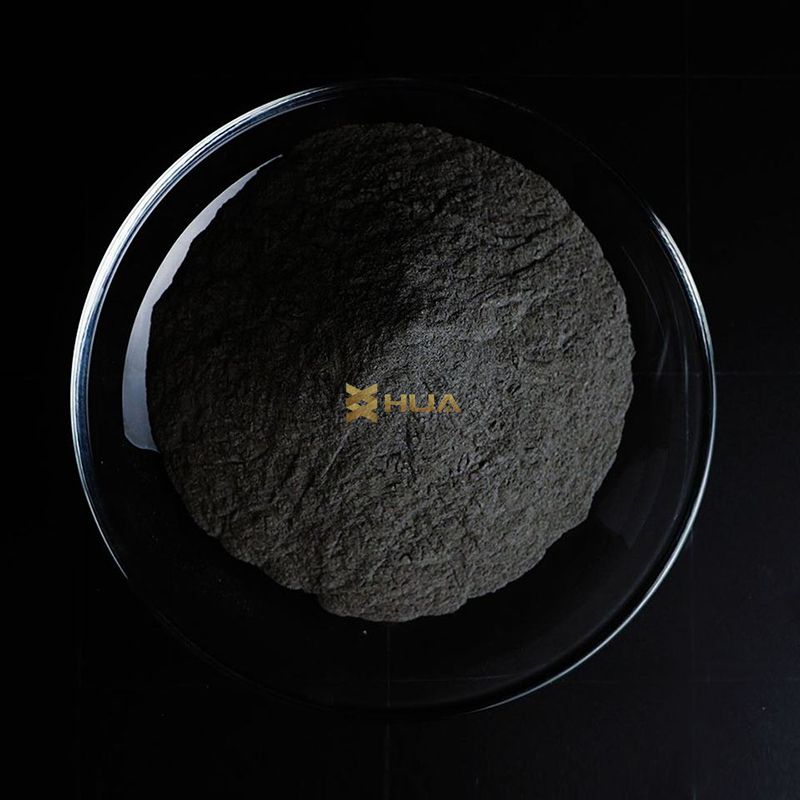

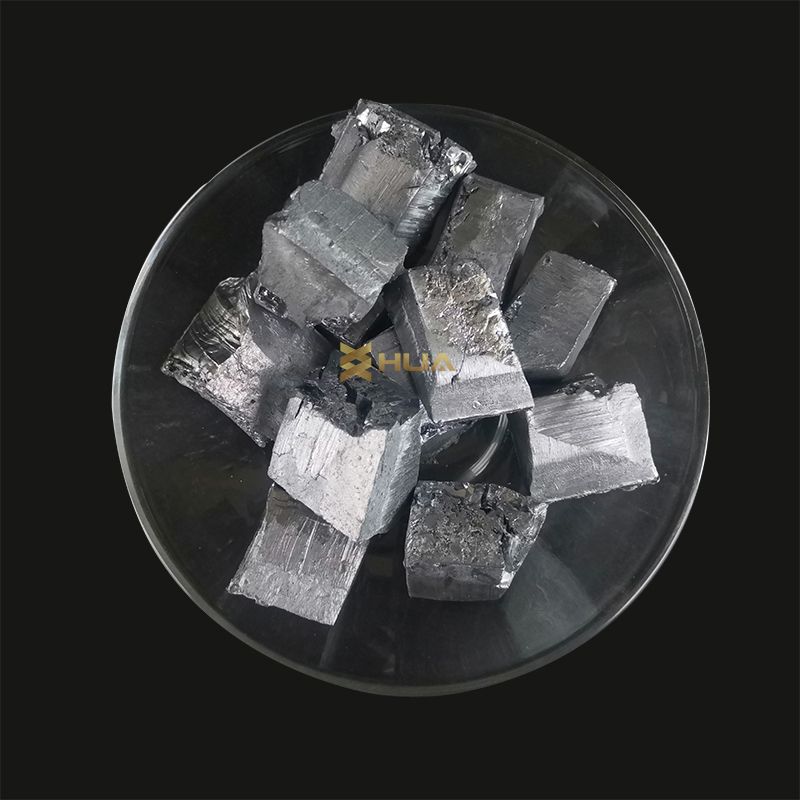

titanium carbonitride coating powder

Product Description

Titanium carbonitride powder is a hard alloy material, composed of titanium, carbon and nitrogen elements. It has excellent wear resistance, high temperature hardness and good toughness, so it is widely used in the manufacture of high-performance cutting tools, such as drills, milling cutters and turning tools. In addition, it can also be used to manufacture high-temperature structural materials and wear-resistant parts, such as aero-engine components, automotive parts and medical devices. In short, titanium carbonitride powder is a high-performance cemented carbide material with excellent wear resistance, high temperature hardness and good toughness, which can be applied to various fields, such as machinery manufacturing, petroleum and chemical industry.

Specification

|

TiCN Titanium Carbide Nitride Powder Composition % |

||||||||

|

Grade |

TiCN |

Ti |

N |

T.C |

F.C |

O |

Si |

Fe |

|

≧ |

≤ |

≤ |

≤ |

|||||

|

TiCN-1 |

98.5 |

75-78.5 |

12-13.5 |

7.8-9.5 |

0.15 |

0.3 |

0.02 |

0.05 |

|

TiCN-2 |

99.5 |

76-78.9 |

10-11.8 |

9.5-10.5 |

0.15 |

0.3 |

0.02 |

0.05 |

|

TiCN-3 |

99.5 |

77.8-78.5 |

8.5-9.8 |

10.5-11.5 |

0.2 |

0.4 |

0.4 |

0.05 |

|

Size |

1-2um, 3-5um, |

|||||||

|

Customized size |

||||||||

Application

1. Ti(C,N)-based cermet cutting tools

Ti(C,N)-based cermet is a very important structural material. Compared with WC-based cemented carbide, the tool prepared with it shows higher red hardness, similar strength, thermal conductivity and friction coefficient in processing. It has a higher lifespan or can adopt a higher cutting speed under the same lifespan, and the processed workpiece has a better surface finish.

2. Ti(C,N)-based cermet coating

Ti(C,N)-based cermet can be made into wear-resistant coatings and mold materials. Ti(C,N) coating has excellent mechanical and tribological properties. As a hard and wear-resistant coating, it has been widely used in cutting tools, drills and molds, and has broad application prospects.

3. Composite ceramic materials

TiCN can be combined with other ceramics to form composite materials, such as TiCN/Al2O3, TiCN/SiC, TiCN/Si3N4, TiCN/TiB2. As a reinforcement, TiCN can improve the strength and fracture toughness of the material, and can also improve the electrical conductivity.

4. Refractory materials

Adding non-oxides to refractory materials will bring some excellent properties. Studies have shown that the presence of titanium carbonitride can significantly improve the performance of refractory materials.