Boron Nitride

Product Description

Boron nitride has the characteristics of hardness, high melting point, corrosion resistance and high thermal conductivity, which makes it widely used in many fields. The hardness of boron nitride is very high, similar to diamond. This makes boron nitride ideal for manufacturing high-hardness materials, such as cutting tools, abrasives, and ceramic materials. Boron nitride has excellent thermal conductivity. Its thermal conductivity is about twice that of metal, making it an ideal material for high temperature applications. Boron nitride is often used as a heat dissipating material and can cope with high temperature and high pressure environments. Boron nitride also has good chemical stability and corrosion resistance. It can resist the corrosion of acids, bases and most organic solvents, so it is widely used in the chemical industry and the petroleum industry.

Specification

| 技术指标 Technical Item | 单位 Unit | HRBN系列产品编号/HRBN Series Product Code | 方法/设备 Method/Device | |||||||

| HRBN-30 | HRBN-60 | HRBN-100 | HRBN-120 | HRBN-160 | HRBNL-120 | HRBNL-200 | HRBNL-250 | |||

| 粒度分布 Particle Size (D50) | µm | 30 | 65 | 100 | 120 | 180 | 120 | 200 | 260 | Light Scattering P-9 Light Scattering/OMEC TopSizer |

| 比表面积 Specific Surface Area | m2/g | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | 3H-2000A Specific Surface Area Anylyer |

| 电导率 Electrical Conductivity | µS/cm | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | Mettler FE-30 Conductivity Meter |

| pH Value | - | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | Mettler FE-20 pH Meter |

| 振实密度 Tapped Density | g/cm3 | 0.3 | 0.45 | 0.45 | 0.45 | 0.45 | 0.35 | 0.37 | 0.37 | BT-303 |

| BN | % | ≥99.3 | ≥99.3 | ≥99.3 | ≥99.3 | ≥99.3 | ≥99.3 | ≥99.3 | ≥99.3 | ICP-AES |

Packaging Details

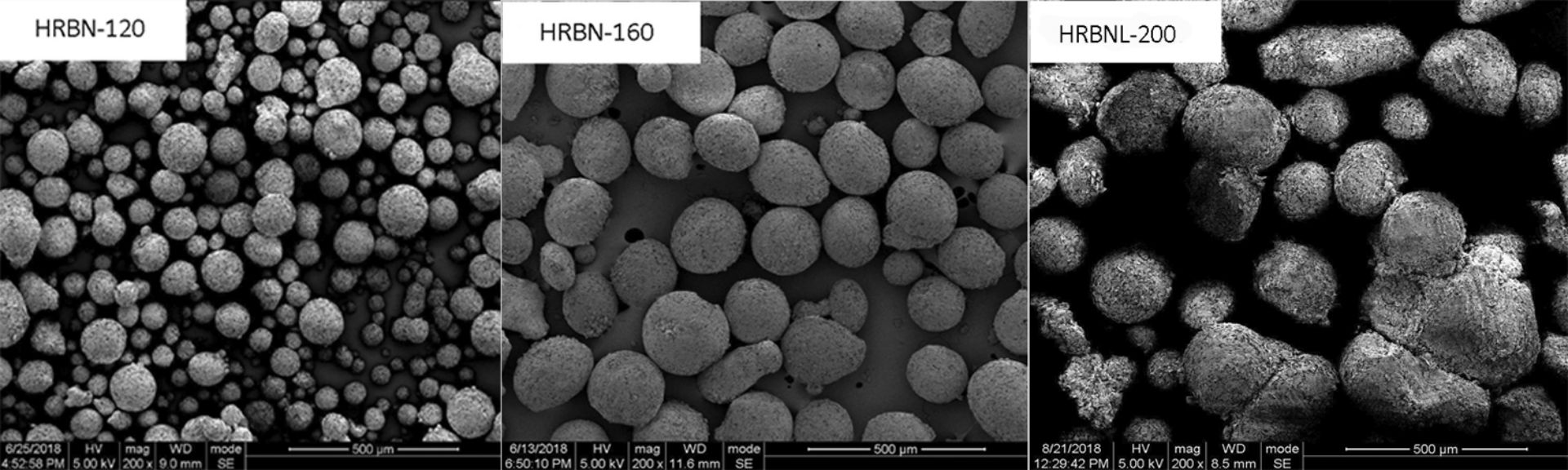

Sem

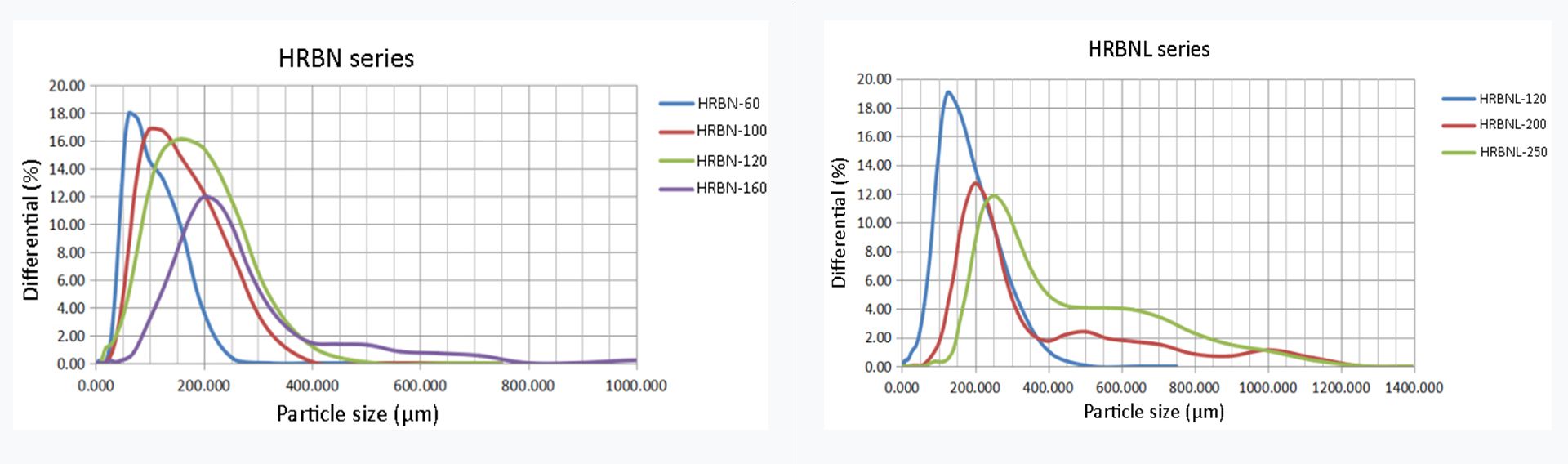

Particle size

Product Features

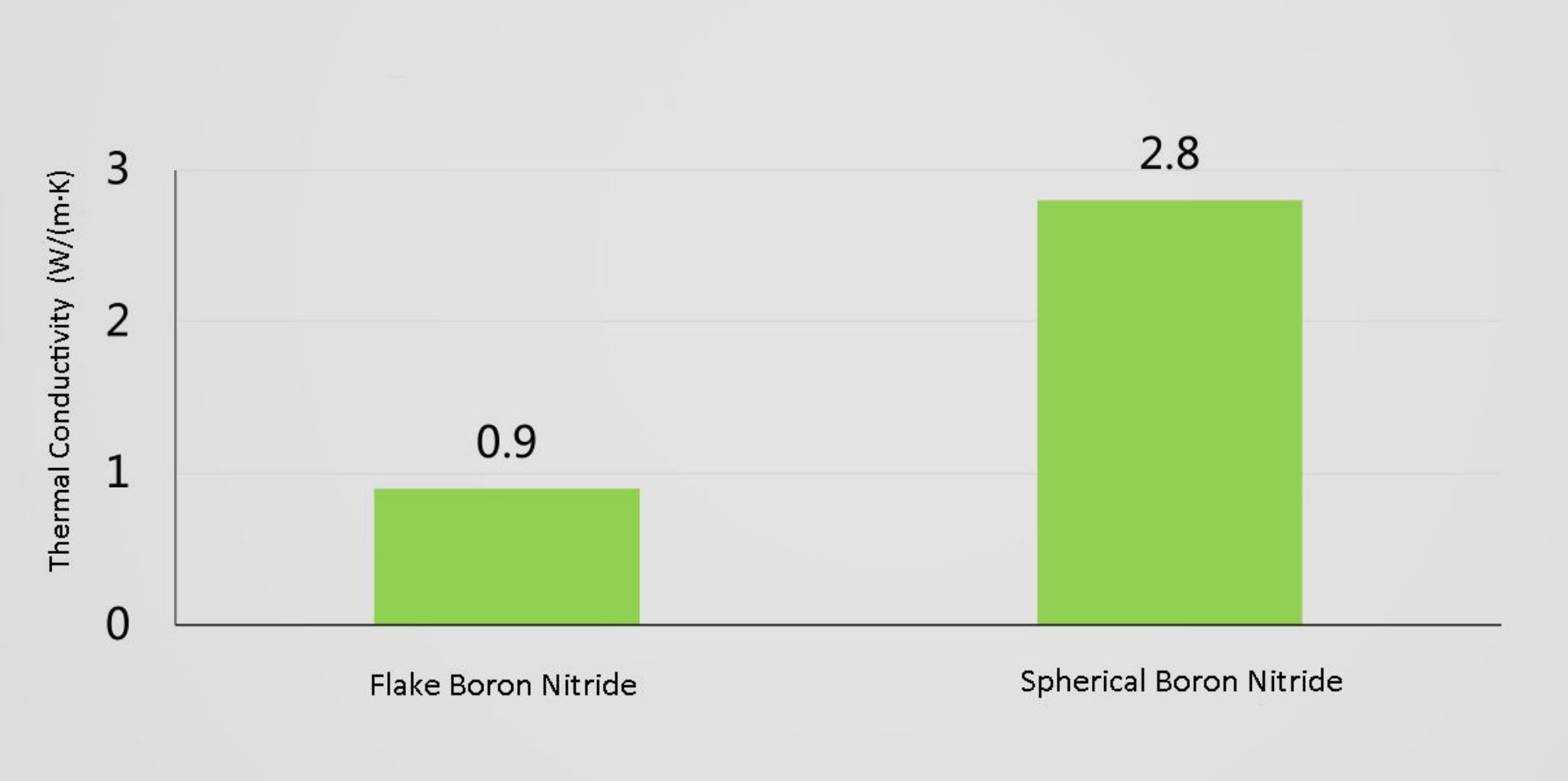

High thermal conductivity ;

Low S.S.A.;

High filling ability (for low shear machining applications)

Thermal isotropic;

The particle size is uniform, and the distribution is very narrow, conducive to achieve a stable match with other fillers in the application.

Main applications

Electronic packaging;

High frequency power devices;

Solid state LED lighting;

Thermal interface materials: thermal pads, thermal silicone grease, thermally conductive paste, thermally conductive phase change materials;

Thermal conductivity alumina-based CCL, printed circuit board prepreg;

Thermally conductive engineering plastics.