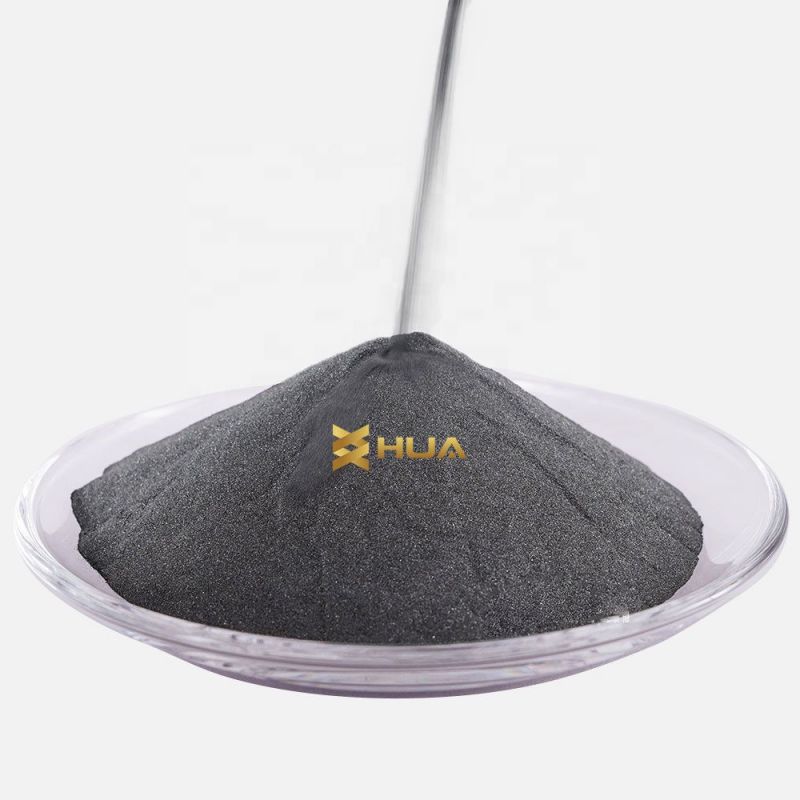

Tungsten carbide welding wire

Product Description

The main components of tungsten carbide welding wire are tungsten carbide and cobalt, which has high hardness, high melting point and high toughness, making it able to withstand large mechanical stresses and high temperatures. The process of manufacturing tungsten carbide wire is very complex, including powder preparation, wire forming and hardening steps. First, tungsten carbide and cobalt powder are fused at high temperatures and then formed into a welding wire of a specific diameter by a wire drawing machine. Finally, the wire is hardened to ensure its mechanical properties. Tungsten carbide welding wire is an efficient and durable welding material, because of its unique material characteristics and manufacturing process, is widely used in many industrial fields. Especially in the fields of petroleum, chemical industry, electricity, construction and machinery manufacturing. It is used to repair worn or damaged parts, as well as to enhance the strength and durability of metal materials. Due to its high hardness and melting point, tungsten carbide welding wire can withstand high temperature and pressure, while having good corrosion resistance and wear resistance, can extend the service life of equipment.

Specification details

|

Flexible Welding Rope Specification: |

|||

|

Item: |

Diameter(mm) |

Length(mm) |

Weight/Coil |

|

HR699A |

Φ4.0 |

Coil |

15 |

|

HR699B |

Φ5.0 |

Coil |

15 |

|

HR699C |

Φ6.0 |

Coil |

15 |

|

HR699D |

Φ8.0 |

Coil |

15 |

Application

1.Hardfacing of ferritic and austenitic steels (steel castings),

2.overlaying --mixer blades,

3.screws & conveyors in the chemical,

4.dye and food industries

5.be used for stabilizer blades in the petroleum industry

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.