Iron based alloy powder for thermal spray powder

Product Description

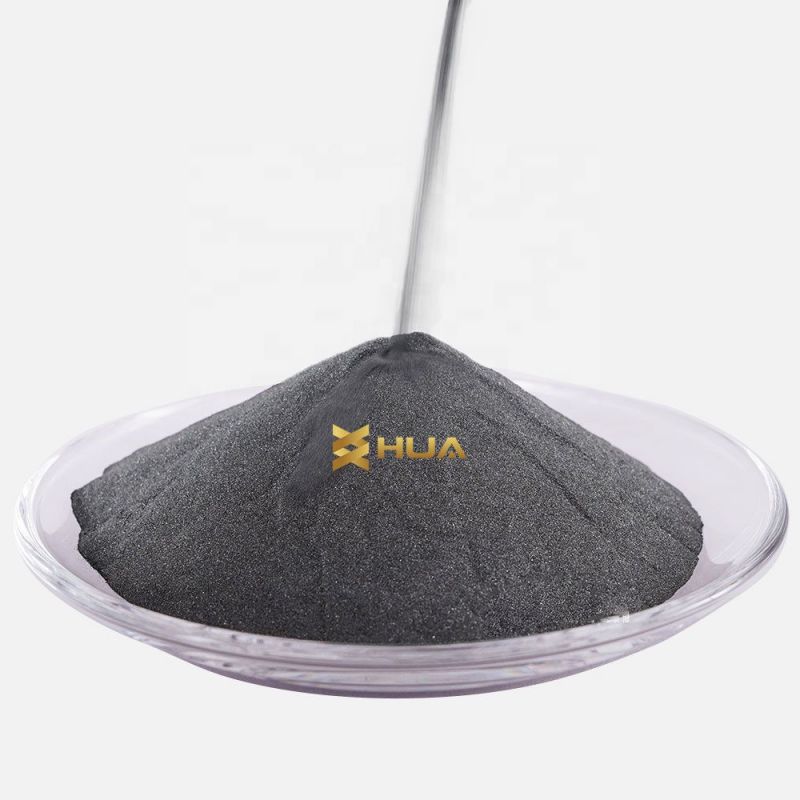

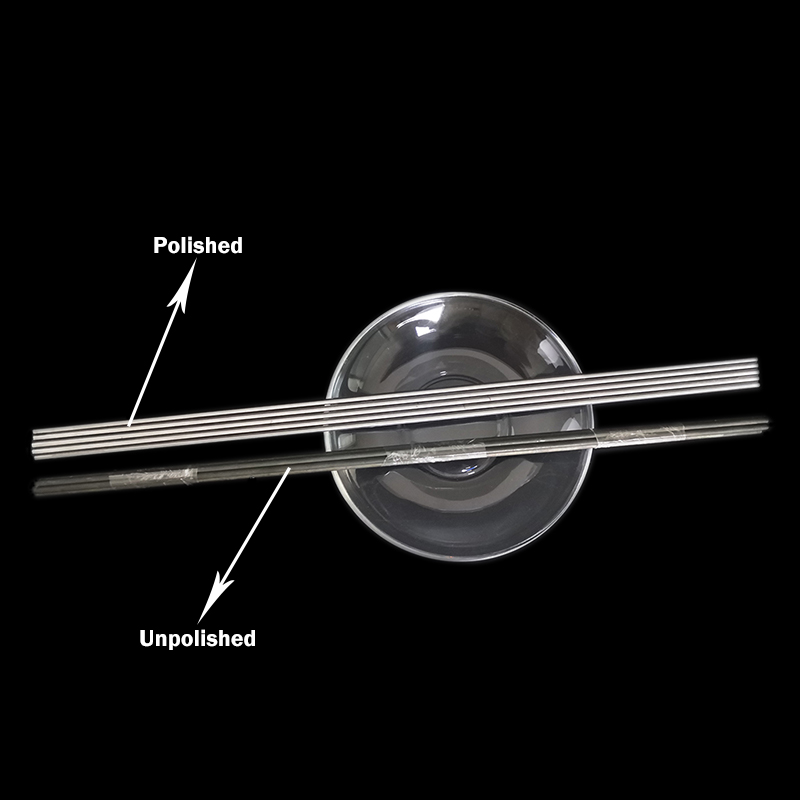

Iron based alloy powder refers to the alloy powder with metallic iron as the main component. It can be applied and studied well in iron products, thermal spraying field and powder metallurgy process. The iron based alloy powder we provide has the characteristics of high purity, uniform particle size and good sphericity. Can be used to produce powder metallurgy machinery parts. Suitable for powder metallurgy structural parts, widely used in automobiles, motorcycles, household appliances, electric tools, office machinery, agricultural machinery, machine tools, instrumentation, textile machinery, metallurgical machinery and other fields.

Specification

| Atomized Iron Based Alloy Powder | |||||

| Grade | Chemistry | Flow Density | Size | Hardness | Application |

| FeNiCrSiB Fe30 |

C 0.2 |

20-25s/50g3.8g/cm3 | -150+45um -106+45 um |

30HRC | sWith favorable antifaingue propetly, applicable for circumstance under repeated impact but with low hardness requirement |

| FeNiCrSiWB Fe45 |

C 0.6 |

20-25s/50g 3.8g/cm3 |

-150+45um -106+45 um |

45HRC | sFor repair of sealing face of valve and vulnerable parts of machine |

| FeNiCrSiB Fe55 |

C 1.2 |

20-25s/50g 3.8g/cm3g |

-150+45um -106+45 um |

55HRC | sFor repair of harrow piece shovel tooth, petroleum drilling rod joint and scraper shaft |

| FeNiCrSiB Fe60 | C 1.5 Si 3.5 B 3.0 Cr 35 Ni 15 Fe Bal |

20-25s/50g 3.8g/cm3g |

-150+45um -106+45 um |

60HRC | sFor repair of harrow piece shovel tooth, petroleum drilling rod joint and scraper shaft |

| FeNiCrSiB Fe55T | C 0.8 Si 2.0 B 1.5 Cr 14 Ni 6 Fe Bal |

20-25s/50g 3.8g/cm3g |

-150+45um -106+45 um |

55HRC | sFor repair of harrow piece shovel tooth, petroleum drilling rod joint and scraper shaft |

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.