Zirconium Nickel Alloy Powder

Product Description

Zirconium-nickel alloy is a kind of metal compound with important application value. It is an alloy composed of two metal elements, zirconium and nickel. Zirconium-nickel alloy is a kind of metal material with excellent comprehensive properties, which has excellent corrosion resistance, high temperature strength, mechanical properties and machining properties. Zirconium-nickel alloy has excellent corrosion resistance and can maintain good oxidation resistance and fatigue resistance at high temperatures. In addition, zirconium nickel alloy also has good mechanical properties, can maintain good strength and ductility at high temperatures.

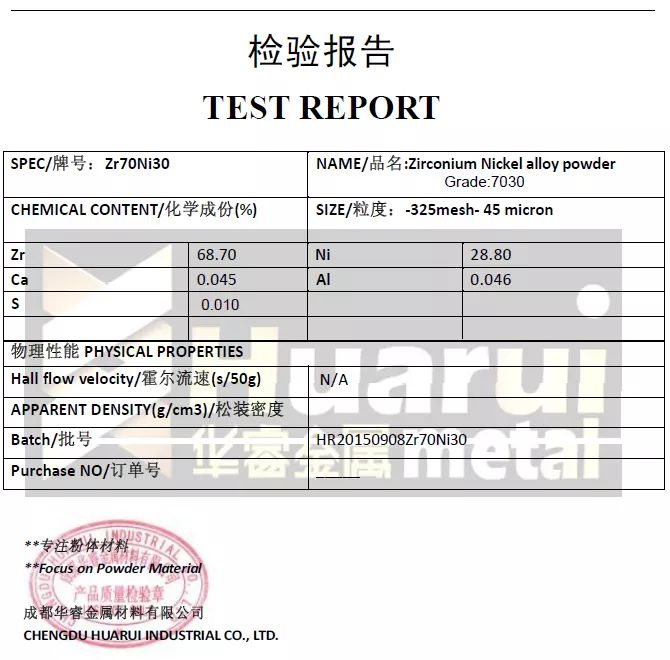

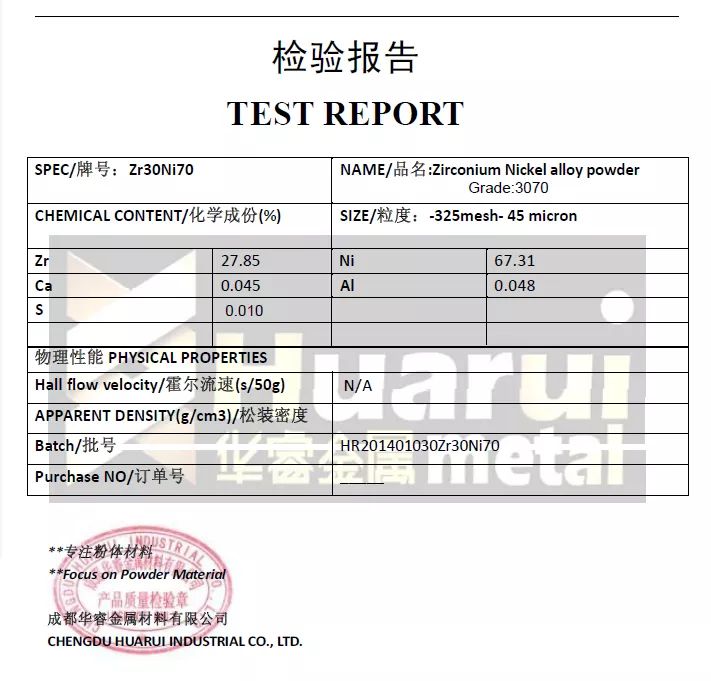

Specification

| Grade | Zr30Ni70 | Zr50Ni50 | Zr70Ni30 | Industry standard |

| Zr | 30.58% | 50% | 70.12% | ± 4% |

| Ni | 69.04% | 50% | 29.18% | ± 4% |

| Ca | 0.05% | 0.05% | 0.05% | ≦0.15% |

| Fe | 0.17% | 0.16% | 0.15% | ≦0.2% |

| Al | 0.10% | 0.01% | 0.01% | ≦0.15% |

| S | 0.01% | 0.01% | 0.01% | ≦0.01% |

| Moisture | 0.001 | 0.001 | 0.001 | ≦0.2% |

Application

Zirconium nickel alloy powder finds application in various pyrotechnic and ordnance areas. It is used in squibs, delay mixtures and initiators.

Coa

Quality control system

Huarui has strict quality management system. We test our products first after we finish our production, and we test again before every delivery, even sample. And if you need, we would like to accept third party to test. Of course if you like, we could provide sample to you to test.

Our product quality is guaranteed by Sichuan Metallurgical Institute and Guangzhou Institute of Metal Research. The long term cooperation with them can save a lot of testing time for customers.