B4C nanopowder Boron carbide powder for welding material

Product Description

Boron carbide is an inorganic substance, usually a gray-black powder. It has a high density (2.55g/cm³), a high melting point (2350 ° C), and excellent chemical stability and neutron absorption. The material is very hard, equal to the hardness of diamond, and has the properties of neutron absorber. This has led to the use of boron carbide in many fields, such as nuclear energy as a neutron absorber, as well as wear resistant materials, ceramic reinforcement phase, lightweight armor, and especially nuclear reactor neutron absorber.

|

Another name |

B2-C、B4C、black diamond、teraboron carbide |

|

CAS NO. |

12069-32-8 |

|

Chemical formula |

B4C |

|

Molar mass |

55.255 g mol |

|

Appearence |

Black powder |

|

Density |

2.52g/cm(solid) |

|

Melting point |

2350°C (2623.15 K) |

|

Boiling point |

>3500 °C (>3773.15 K) |

|

Solubility in water |

Insoluble |

|

Crystal structure |

rhombohedral |

|

Main danger |

harmfu, Irritating |

Specification

|

Grit Size |

Size |

Chemical Composition |

|||

|

B% |

C% |

Fe2O3% |

BC% |

||

|

60# |

315-215 |

78-81 |

17-22 |

0.2-0.4 |

97-99 |

|

80# |

200-160 |

||||

|

100# |

160-125 |

||||

|

120# |

125-100 |

78-80 |

17-22 |

0.2-0.4 |

96-98 |

|

150# |

100-80 |

||||

|

180# |

80-63 |

||||

|

240# |

60-50 |

77-80 |

17-22 |

0.3-0.5 |

96-97 |

|

280# |

50-40 |

||||

|

320# |

40-28 |

||||

|

W40(360#) |

35-28 |

76-79 |

17-21 |

0.3-0.6 |

95-97 |

|

W28(400#) |

28-20 |

||||

|

W20(500#) |

20-14 |

75-79 |

17-21 |

0.4-0.8 |

94-96 |

|

W14(600#) |

14-10 |

||||

|

W10(800#) |

10-7 |

74-78 |

17-21 |

0.4-0.9 |

92-94 |

|

W7(1000#) |

7-5 |

||||

|

W5(1200#) |

5-3.5 |

74-78 |

17-21 |

0.5-0.9 |

90-93 |

|

W3.5(1500#) |

3.5-2.5 |

||||

|

-325# |

<45 |

74-79 |

17-22 |

<0.3 |

92-97 |

|

0-44μm |

<45 |

||||

|

-200# |

<90 |

74-80 |

17-22 |

<0.3 |

94-97 |

|

-100# |

<150 |

||||

|

0-25μm |

<25 |

74-79 |

17-21 |

<0.3 |

92-96 |

|

0-10μm |

<10 |

74-78 |

17-21 |

<0.3 |

91-95 |

|

60#-150# |

250-75 |

77-81 |

17-22 |

<0.3 |

95-98 |

|

40#-120# |

315-106 |

||||

|

30#-60# |

355-250 |

||||

|

Boron carbide |

355-250 |

92-80 |

17-23 |

<0.3 |

90-99 |

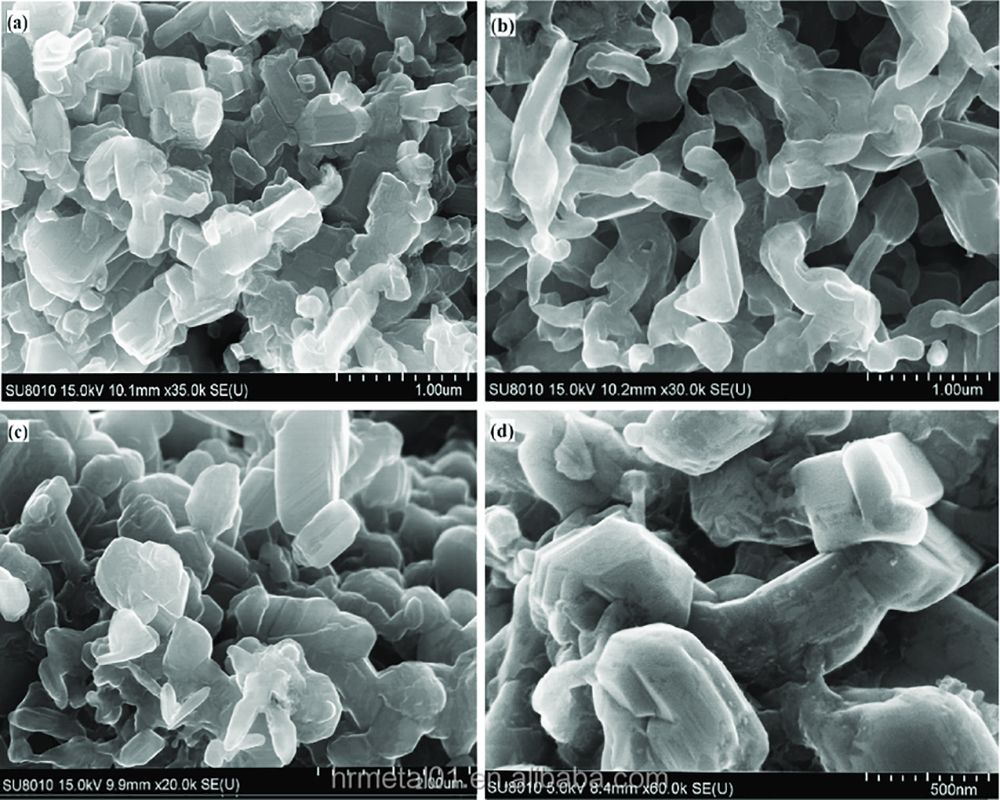

Sem

Package

Advantage

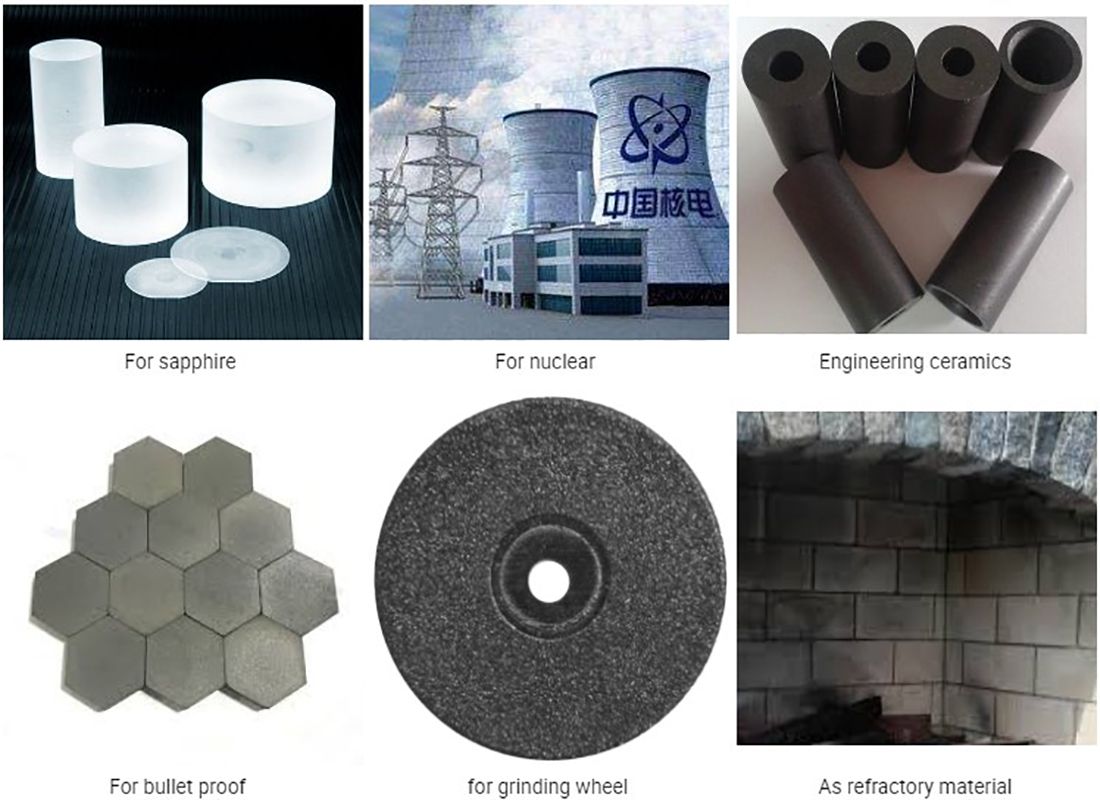

1. High-grade particle grinding material;

2. Make chemical ceramic,glass ,or nozzle;

3. Nuclear reactor and shielding material;

4.Produce bullet proof armor;

5. Improve the service lift of mechanical parts;

6. As additive filler for boron chemical materials;

7. Essential filler for refractory materials.