Titanium Metal Powder high purity 99% Spherical Titanium Powder

Product Description

Titanium powder is silver-gray powder with inhalation capability and is flammable under high temperature or electric spark conditions. The product has high purity, small particle size and high surface activity. Usually used in aerospace, spraying, metallurgy and other industries.

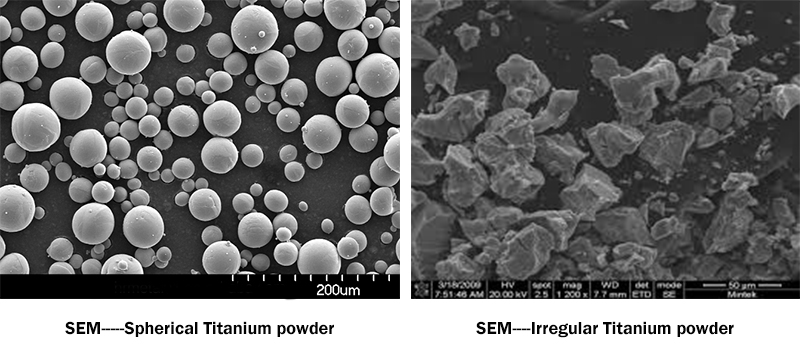

SEM

Specification

|

CPTI ---Chemical Composition |

|||||||||

|

Size: |

O |

N |

H |

C |

Cl |

Fe |

Si |

Mn |

Ti |

|

-60 |

0.18 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

-80 |

0.2 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

-100 |

0.22 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

-200 |

0.25 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

-325 |

0.32 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.5 |

|

-400 |

0.35 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.5 |

|

100-200 |

0.18 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

200-300 |

0.25 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

300-400 |

0.3 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

100-325 |

0.26 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

200-325 |

0.3 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

200-400 |

0.3 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

100-150 |

0.18 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

150-200 |

0.2 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

200-250 |

0.25 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

250-325 |

0.28 |

0.025 |

0.03 |

0.02 |

0.04 |

0.035 |

0.02 |

0.01 |

99.6 |

|

D50=3μm |

1.8 |

0.035 |

0.04 |

0.03 |

0.04 |

0.04 |

0.02 |

0.01 |

98 |

|

D50=5μm |

1.6 |

0.035 |

0.04 |

0.03 |

0.04 |

0.04 |

0.02 |

0.01 |

98 |

|

D50=8μm |

1.5 |

0.035 |

0.04 |

0.03 |

0.04 |

0.04 |

0.02 |

0.01 |

98.3 |

|

D50=11μm |

1.5 |

0.035 |

0.04 |

0.03 |

0.04 |

0.04 |

0.02 |

0.01 |

98.3 |

|

D50=20μm |

1.3 |

0.035 |

0.04 |

0.03 |

0.04 |

0.04 |

0.02 |

0.01 |

98.3 |

Application

The product has high purity, small particle size and high surface activity.

1.powder metallurgy

2.powder metallurgy additions.

3.Specific applications include titanium filters,

4.porous materials,

5.sputtering targets,

6.diamond tools

7.polycrystalline diamond.

Advantage of Huarui Titanium powder with special technology

1.low oxygen content

2.High sphericity with excellent fluidity

3.Less Satellite powder and hollow powder