spherical alumina powder

Product Description

Spherical alumina is a high-performance material with high purity, spherical particles, high hardness, high wear resistance, high corrosion resistance, high thermal stability and good electrical insulation. Spherical alumina has high hardness and strength, which makes it an ideal wear-resistant material. In the fields of ceramics, electronics, chemical industry and construction, spherical alumina is widely used in the manufacture of advanced ceramic materials, advanced wear-resistant bearings, advanced automotive engine parts, etc. Spherical alumina has high corrosion resistance, which enables it to maintain stable performance in harsh environments. For example, in the Marine environment, chemical industry, energy industry and other fields, spherical alumina is used in the manufacture of ships, chemical equipment, power equipment and so on. Spherical alumina has good thermal stability and electrical insulation, so that it can maintain excellent performance in high temperature and high pressure environments. In the field of electronics, spherical alumina is used in the manufacture of high-temperature electronic devices, high-voltage power equipment, etc.

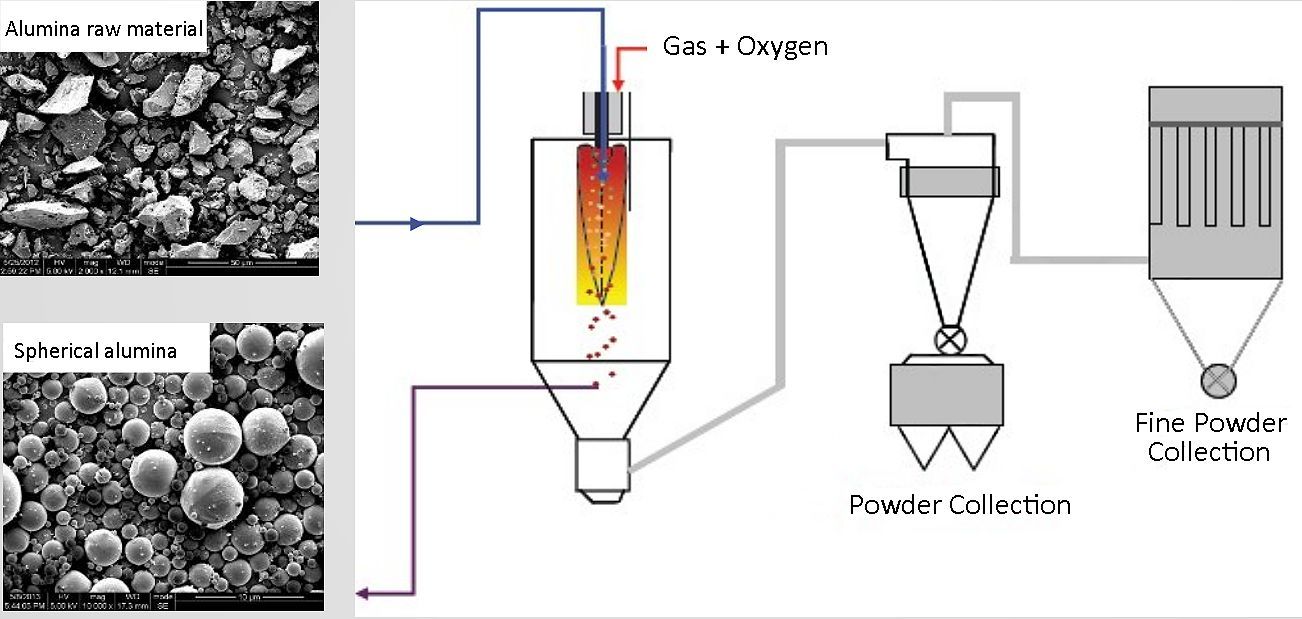

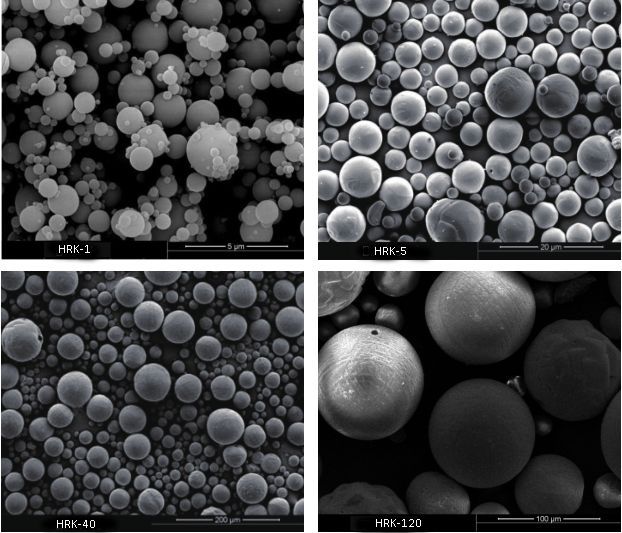

Electron micrograph

Product Features

High Filling: High degree of spheroidization rate, controllable particle size distribution, achieve high density filling for silicone and epoxy resin, to get the mixture with low viscosity and high mobility;

High Thermal Conductivity: Because of its almost perfect ball structure, the filler used in the raw materials can achieve multi-directional heat transmission. The whole mixed system is in state of good dispersion, so final products have excellent thermal conductivity and physical property;

Low Abrasion: Compared with irregular powder, the application of spherical filler can reduce the abrasion of the mixer, molding machines and other equipment, then prolong working life of relevant equipment。

Specification

| 技术指标 Technical item |

单位 Unit |

HRK系列产品编号/HRK Series product Code | ||||||||||

| HRK-1 | HRK-2 | HRK-5 | HRK-10 | HRK-20 | HRK-30 | HRK-40 | HRK-70 | HRK-90 | HRK-120 | |||

| 粒度分布 Particle Size |

(D10) | µm | 0.71 | 0.69 | 2.54 | 4.55 | 10.5 | 16.88 | 23.77 | 44.32 | 55.23 | 92.39 |

| (D50) | µm | 1.08 | 2.18 | 5.52 | 10.43 | 20.8 | 30.52 | 41.54 | 71.54 | 87.96 | 122.98 | |

| (D90) | µm | 3.21 | 5.24 | 9.09 | 20.8 | 37.24 | 48.87 | 66.44 | 106.5 | 134.92 | 172.07 | |

| 比表面积 Specific Surface Area |

m2/g | 1.69 | 1.27 | 0.36 | 0.17 | 0.14 | 0.13 | 0.12 | 0.12 | 0.1 | 0.06 | |

| 电导率 Electrical Conductivity |

u S/cm | 6.07 | 5.4 | 5.65 | 4.05 | 6.87 | 7.95 | 4.65 | 6.18 | 8.15 | 6.45 | |

| PH Value | - | 7.53 | 7.79 | 7.7 | 7.9 | 7.62 | 7.7 | 7.8 | 7.7 | 7.9 | 7.54 | |

| 含水量 Moisture |

% | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | |

| 真密度 True Density |

g/cm3 | 3.71 | 3.7 | 3.74 | 3.76 | 3.79 | 3.79 | 3.81 | 3.87 | 3.88 | 3.89 | |

| 球化率 Spheroidization Rate |

% | 96 | 98 | 98 | 98 | 96 | 98 | 96 | 96 | 95 | 95 | |

| 化学成分 Chemical Composition |

Al2O3 | % | 99.87 | 99.94 | 99.89 | 99.94 | 99.92 | 99.93 | 99.94 | 99.92 | 99.94 | 99.92 |

| SiO2 | ppm | 430 | 30 | 430 | 20 | 150 | 20 | 20 | 30 | 20 | 170 | |

| Fe2O3 | ppm | 140 | 70 | 140 | 40 | 60 | 60 | 50 | 60 | 60 | 140 | |

| Na2O | ppm | 90 | 100 | 10 | 60 | 140 | 90 | 110 | 90 | 70 | 90 | |

Sem

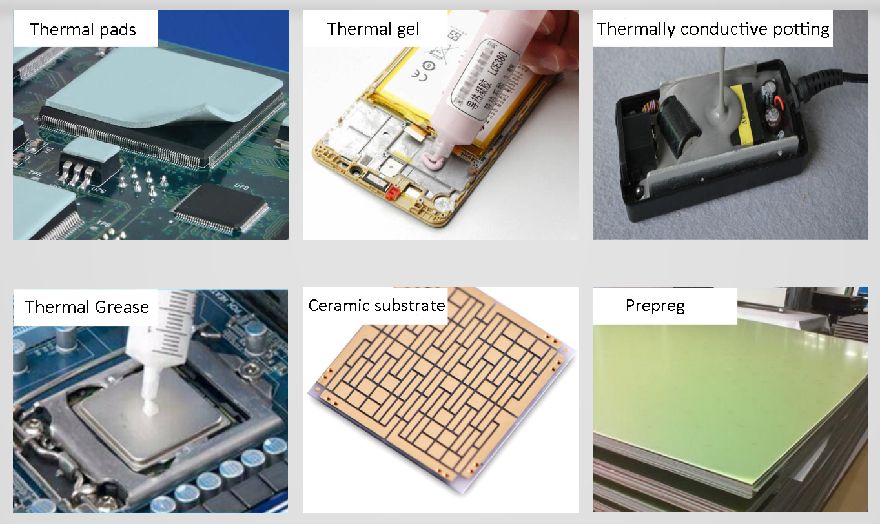

Application

Thermal Interface Materials: thermal silica pad, thermal grease, thermally conductive potting glue, phase change materials

Thermally Conductive Engineering Plastics: LED lamp cover, switch shell,electronic products shell, electrical products heat dissipation parts;

Al-based Copper Clad Laminate: high-power LED circuit substrate, power circuit boards, etc;

Alumina Ceramic Filters;

Thermal Spray Coating.