Cobalt Base Alloy welding Rods stellite rode prezzo

Product Description

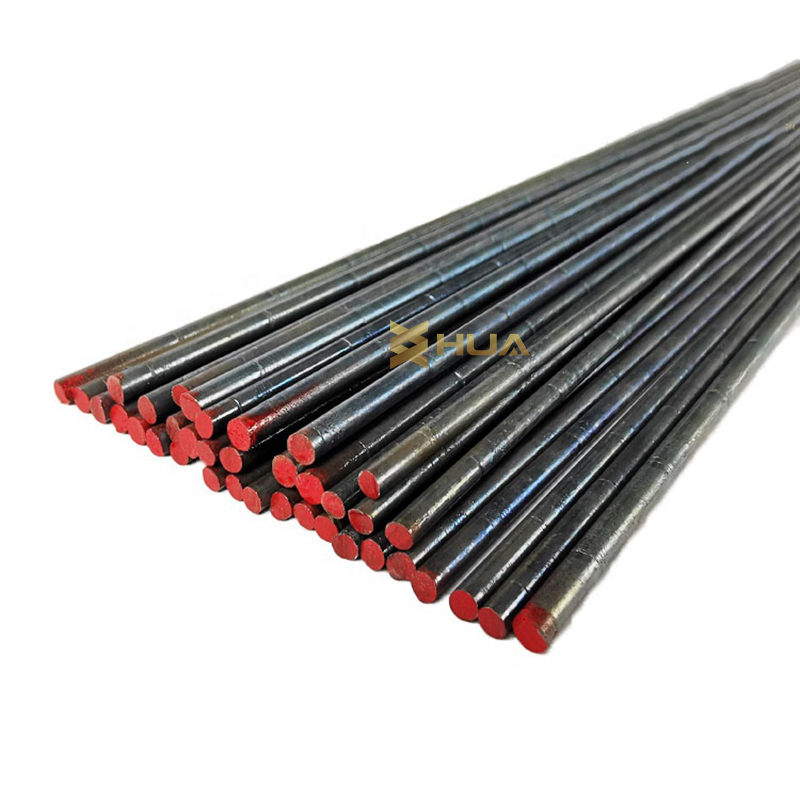

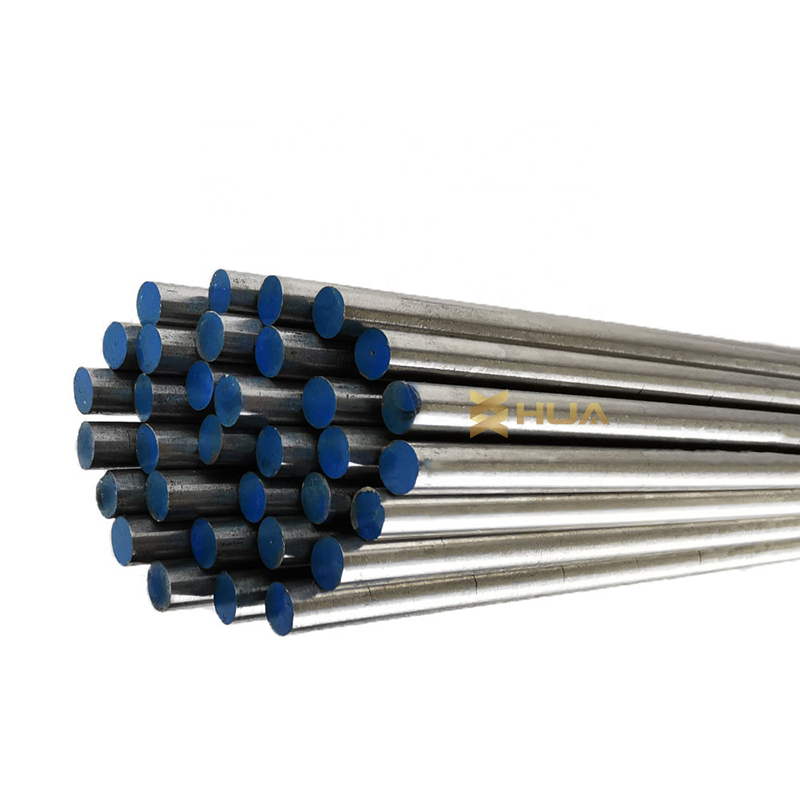

Tig Welding Co 1 6 Bar Cobalt Base Alloy Bare Rods

Cobalt-Based Alloy Bare Rod:

- AWS RCoCr-C (HR CO1)

- AWS RCoCr-A (HR CO6)

- AWS RCoCr-B (HR CO12)

AWS RCoCr-C (1#)

It has excellent wear and heat resistance at high temperature.

Recommended use for making valve seal inserts , rotating sealing ring, drill heads, cutter edge ,etc

AWS RCoCr-A (6#)

The most widely used Cobalt Alloy with good mechanical properties at different temperatures, Recommended use for making valve seat material, hot shear blade, high temperature valve , turbine blade ,etc.

AWS RCoCr-B (12#)

It has excellent resistance on high heat, corrosion and abrasion. Recommended use for making high-pressure valve, shear edge, sawteeth, etc.

AWS RCoCr-B (#21)

It has excellent resistance on high heat, corrosion and abrasion. Recommended use for making fuild valve,brass casting die , vlave seat, etc.

Specification

| NO | Chemical composition(%) | ||||||||

| C | Cr | Si | W | Ni | Fe | Mn | Mo | Co | |

| HR-DCo1 | 2.1 | 30 | 1 | 14 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo6 | 1 | 30 | 1 | 4.6 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo12 | 1.4 | 30 | 1 | 9 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo21 | 0.2 | 28 | 1 | --- | ≤3.0 | ≤5.0 | ≤2.0 | 5.5 | Bal |

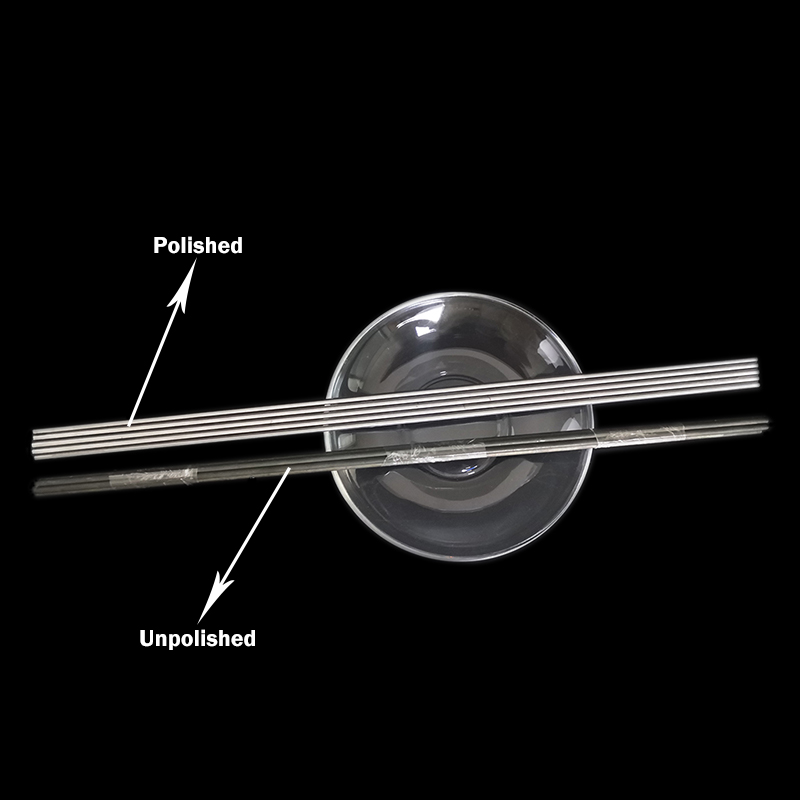

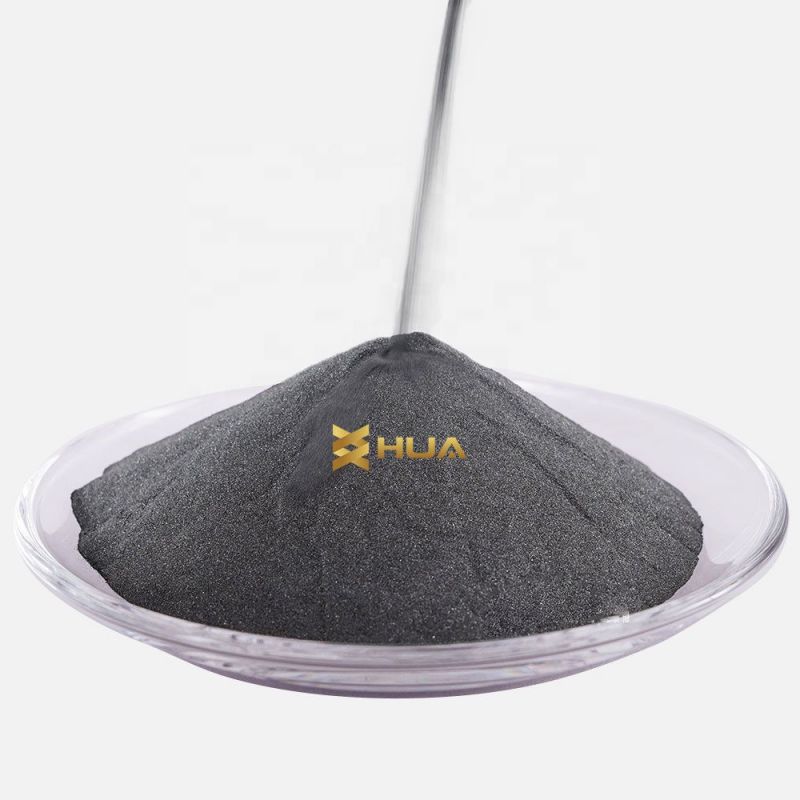

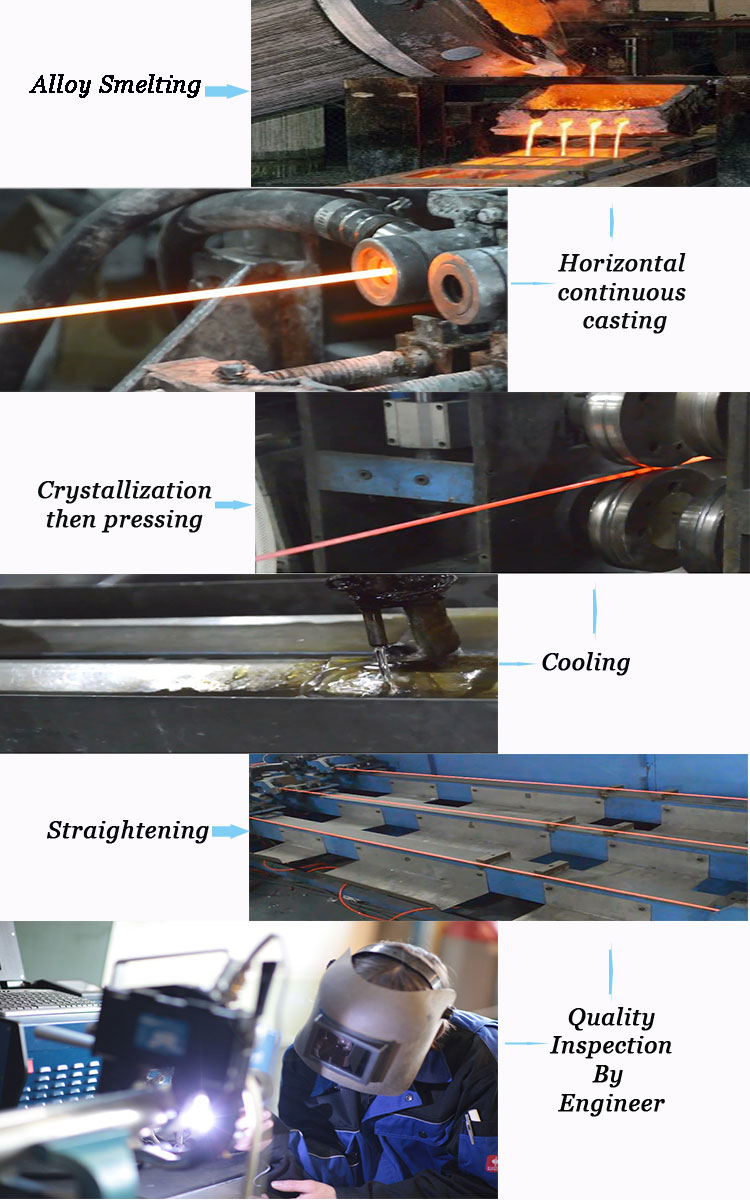

Production Process

Application

It is used for occasions where good performance is required under the conditions of wear and corrosion resistance at high temperature. Such as automobiles, internal combustion engine valves, high temperature and high pressure valves, hot shear blades, inner and outer rings of bearings, hot forging dies, etc.