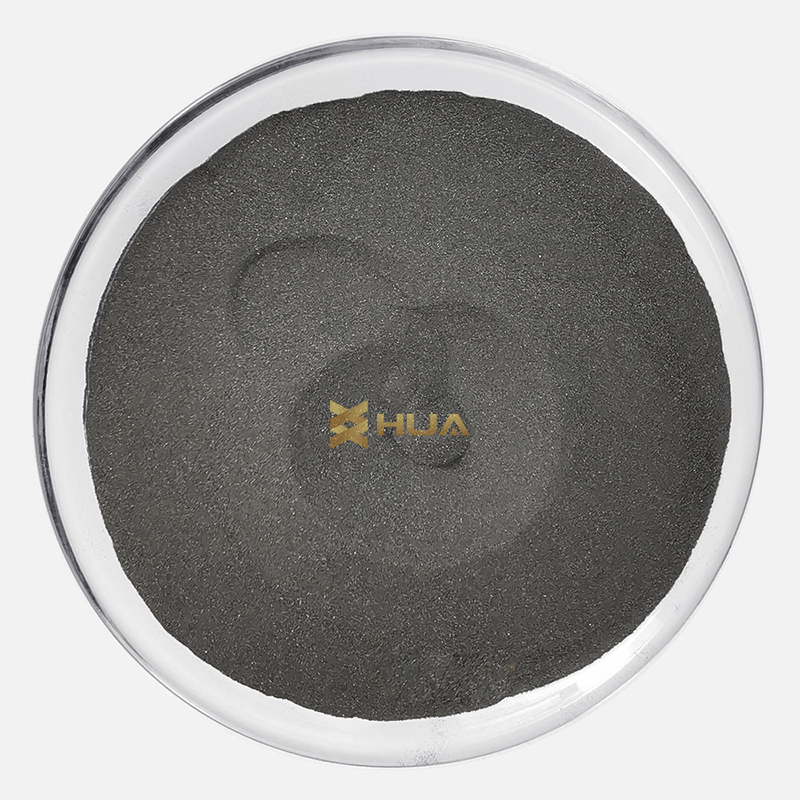

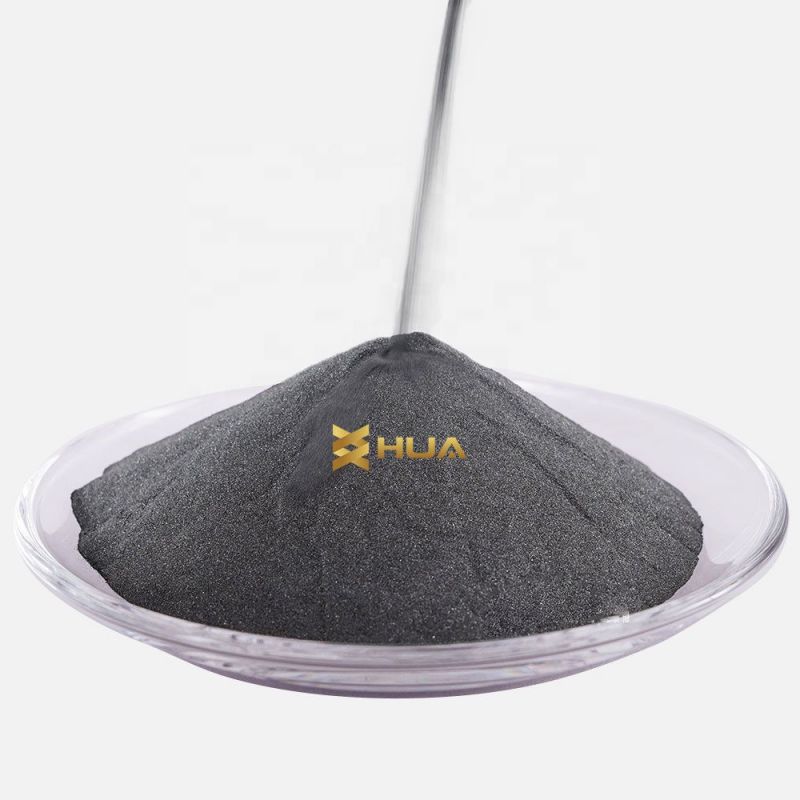

Co base cobalt based alloy metal powder for welding spraying

Product Description

Cobalt based alloy is a kind of alloy with cobalt as the main component, containing a considerable amount of nickel, chromium, tungsten and a small amount of molybdenum, niobium, tantalum, titanium, lanthanum and other alloying elements, occasionally also containing iron. According to the composition of the alloy, they can be made into welding wire, powder for hard surface surfacing, thermal spraying, spray welding and other processes, can also be made into casting and forging parts and powder metallurgy parts.

Specification

|

Item |

HR-Co1 |

HR-Co6 |

HR-Co12 |

HR-Co21 |

|

HRC |

48 |

38 |

42 |

28 |

|

C |

2.4 |

1.15 |

1.4 |

0.25 |

|

Cr |

30.5 |

29 |

29.5 |

27.5 |

|

Si |

1 |

1.1 |

1.45 |

2 |

|

W |

12.5 |

4 |

8.25 |

0.15 |

|

Fe |

3 |

3 |

3 |

2 |

|

Mo |

1 |

1 |

1 |

5.5 |

|

Ni |

3 |

3 |

3 |

2.5 |

|

Co |

Bal |

Bal |

Bal |

Bal |

|

Mn |

0.25 |

0.5 |

1 |

1 |

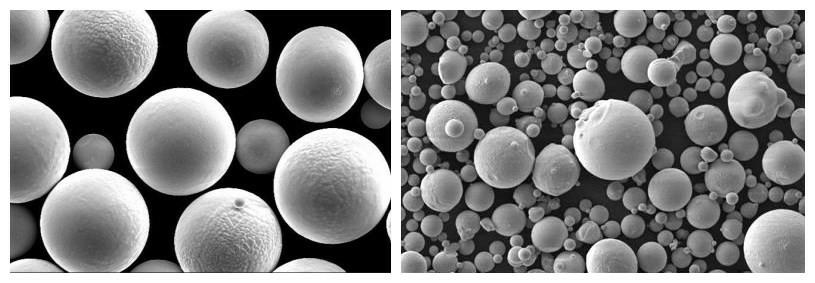

SEM

Application

Cobalt-based alloys have high strength, good resistance to thermal fatigue, thermal corrosion and abrasion, and good weldability at temperatures above 980℃. Suitable for aviation jet engine, industrial gas turbine, ship gas turbine guide vane and nozzle guide vane and diesel nozzle etc.

1.Hardfacing

2.Wear-resistant Welding TIG/MIG

3.Thermal spray PTA/HVOF

HUARUI cobalt alloy powder advantage:

● high sphericity

● high chemical composition homogeneity

● high apparent / tapping density

● Low inclusions content

● Low oxygen content

● High flowability

● Uniform surface thickness and low porosity