Thermal Spray Nickel Based Alloy Powder For Laser Cladding

Product Description

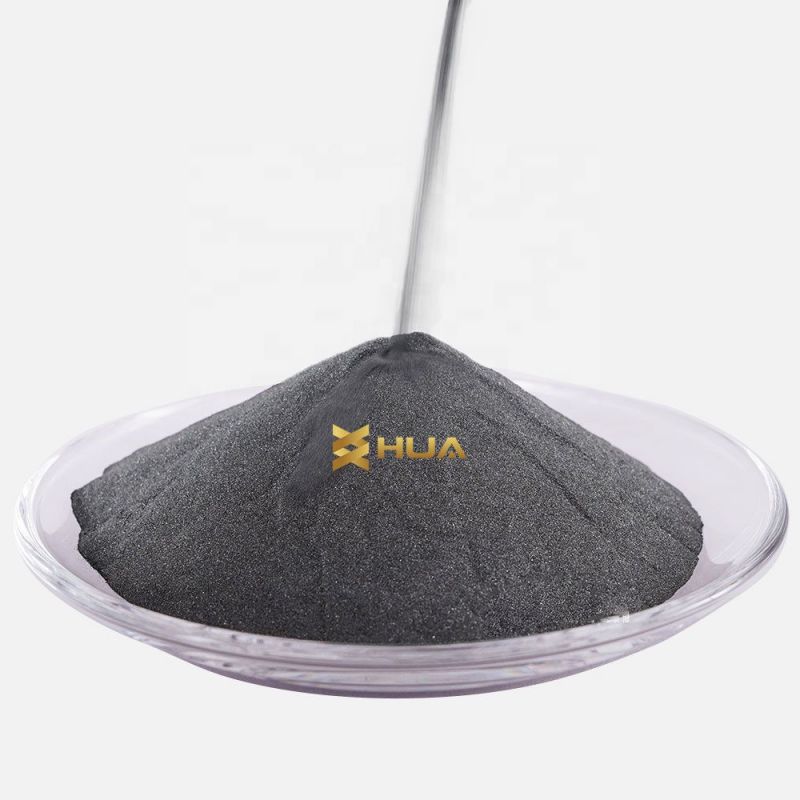

Gas Atomized Ni Base Alloy Nickel Based Powder For Thermal Spray Welding.

Nickel-based self-fluxing alloy powder mainly refers to Ni-Cr-B-Si alloy and Ni-B-Si alloy. These alloys have low melting point, good self-fluxing property and good comprehensive properties such as wear resistance, corrosion resistance, heat resistance and oxidation resistance.Is the earliest and most widely used self-fluxing alloy.

Specification

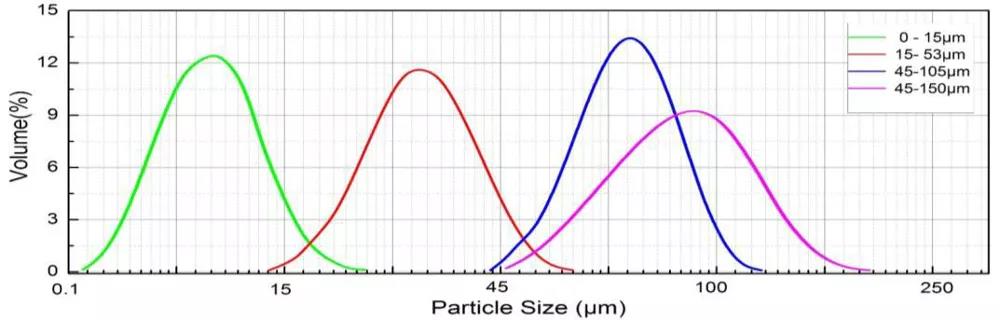

| Item | Technology | Flow | Density | Hardness | Size | Content | Applications |

| HRNi20A | Gas Atomized | 12-17s/50g | 3.5-4.5g/cm3 | 18-22HRC | -106+45um -90+45um |

C:0.1 Cr:4.5 Si:2.0 B:0.7 Ni:bal. |

Flame spray/fusing,Glass mould, various casting dies. |

| HRNi22A | Gas Atomized | 12-17s/50g | 3.5-4.5g/cm3 | 20-24HRC | -106+45um -90+45um |

C:0.2 Cr:1.0 Si:2.8 B:1.4 Fe:1.0 Mn:0.1 Ni:bal. |

Flame spray/fusing Glass mould, various casting dies. |

| HRNi25 | Gas Atomized | 12-17s/50g | 3.5-4.5g/cm3 | 22-27HRC | -106+45um -90+45um |

C:0.2 Cr:1.0 Si:3.5 B:1.5 Fe:8.0 Ni:bal. |

Flame spray/fusing Glass mould, various casting dies. |

| HRNi28A | Gas Atomized | 12-17s/50g | 3.5-4.5g/cm3 | 26-30HRC | -106+45um -90+45um |

C:0.1 Cr:3.0 Si:2.6 B:1.0 Ni:bal. |

Flame spray/fusing Glass mould, various casting dies. |

| HRNi35 | Gas Atomized | 12-17s/50g | 3.5-4.5g/cm3 | 32-37HRC | -106+45um -90+45um |

C:0.3 Cr:10 Si:3.5 Fe:10 B:2.0 Ni:bal. |

Flame spray/fusing Glass mould, various casting dies. |

| HRNi37A | Gas Atomized | 12-17s/50g | 3.5-4.5g/cm3 | 35-40HRC | -106+45um -90+45um |

C:0.15 Cr:4.5 Si:2.6 B:1.2 Ni:bal. |

Flame spray/fusing Glass mould, various casting dies. |

| HRNi45A | Water atomized | 17-21s/50g | 3.5-4.5g/cm3 | 42-47HRC | -106+45um -90+45um |

C:0.4 Si:3 B:2.6 Cr:12 Fe:5 Ni:bal. |

Flame spray/fusing HVOF, Seal surface, punch,valve, piston etc. |

| HRNi50A | Water atomized | 17-21s/50g | 3.5-4.5g/cm3 | 45-50HRC | -106+45um -90+45um |

C:0.5 Si:3.0 B:3.0 Cr:12 Fe:5 Ni:bal. |

Flame spray/fusing HVOF, Seal surface, oil plunger and shaft etc. |

| HRNi55A | Water atomized | 17-21s/50g | 3.5-4.5g/cm3 | 52-55HRC | -106+45um -90+45um |

C:0.8 Si:4.0 B:3.0 Cr:14 Fe:5.0 Ni:bal. |

Flame spray/fusingHVOF, Seal surface, oil plunger and shaft etc. |

| HRNi60A | Water atomized Gas atomized | 17-21s/50g | 3.5-4.5g/cm3 | 55-60HRC | -106+45um -90+45um |

C:0.9 Si:4.0 B:3.2 Cr:16 Fe:5.0 Ni:bal. |

Flame spray/fusing HVOF, good corrosion resist, high hardness, good wear resist performance, low friction coefficient. |

| HRNi60CuMo | Water atomized Gas atomized |

17-21s/50g | 3.5-4.5g/cm3 | 55-60HRC | -106+45um -90+45um |

C:0.9 Si:4.0 B:4.0 Cr:16 Cu:3.0 Mo:3.0 Fe:5.0 Ni:bal. |

Flame spray/fusing HVOF,fix, impeller, piston, valve etc. |

| HRNi65A | Water atomized | 17-21s/50g | 3.5-4.5g/cm3 | 60-65HRC | -106+45um -90+45um |

C:1.1 Si:4.0 B:4.0 Cr:18 Fe:5.0 Ni:bal. |

Flame spray/fusingHVOF, higher hardness than Ni60A, wire roller, plunger, conveyor roller etc. |

| HRNI625 | Water atomized Gas atomized | 17-21s/50g | 3.5-4.5g/cm3 | 8-15HRC | -106+45um -90+45um -45+15um |

C:0.1 Si:0.5 B:0.5 Cr:21 Mo:8.5 Nb:4.0 Fe:5.0 Mn:0.5 Ni:bal. |

Flame spray/fusing HVOF, good corrosion resst and anti-high temperature oxided performance, |

| PS: We also offer customized services | |||||||

SEM

Application

1.Covering special layer on iron and steel parts and some glass moulds repairing.

2.Pre-protection and repairing or strengthening merchannical parts.

3.For FLS/PTA/APS/Laser Cladding application with blending Ni or Nickel base alloy powder layers.

4.Generate more dense coating compared with FTC, and with better hardness and wearness.